Models:

2102, 2103, 2104,

2105, & 2106

"Manufactured in North America"

Applicable to Software Version 2.00-2.12

Owner's and Installer's Manual

for

Room Heating Units

For Customer Use

Please record your model and serial number below. This number is found on the identication

label located on the lower portion of the heater's left side panel. Retain this information for future

reference.

Model No. __________________________________________________________________________________

Serial No. ____________________________________________________________________

Safety Alert Symbols

Three safety alert symbols may be used to

alert you to personal safety instructions. They

are:

• Electrical (1 & 4)

• Mechanical (2)

• Fire (3)

These safety alert symbols are used to alert you to hazards. Obey all safety messages that follow

these symbols to avoid possible injury or death.

Signal Words

Signal words that may appear next to the safety alert symbol are:

• DANGER

• WARNING

• CAUTION

• IMPORTANT

• NOTE

Carefully read and understand the instructions before you continue.

DANGER indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death

or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous situation which, if

not avoided, could result in minor or moderate injury.

IMPORTANT indicates a special instruction or procedure which, if not followed, may

cause damage to the equipment.

NOTE indicates additional information about a subject or procedure for a more efcient or

convenient installation.

• The equipment described herein is intended for installation by a qualied technician

in compliance with applicable local, state, and national codes and regulations.

• To insure proper installation and operation of this product, completely read all

instructions prior to attempting to assemble, install, operate, maintain or repair

this product. Upon unpacking of the system, inspect all parts for damage prior to

installation and start-up.

• This manual should be retained by the owner upon completion of the installation and

made available to service personnel as required.

• Disclaimer: In compiling this manual, Stees has used its best judgement based upon

information available, but disclaims any responsibility or liability for any errors or

miscalculations contained herein, or any revisions hereof, or which result, in whole or

in part, from the use of this manual or any revisions hereof.

Personal Safety Instructions

Important

1. DO fully assemble the heater before energizing.

2. DOkeepallexplosivematerialsand/orammablegases

away from the room heating unit.

3. DO maintain the placement and clearance requirements.

4. DO keep items away from the discharge air grill area of the

heater.

5. DO disconnect power to all circuits before servicing. This

room heating unit may be connected to more than one

branch circuit.

6. DOcontactaqualiedservicetechnicianforinstallation

of and/or service to this heater to ensure it is installed

and/or serviced in accordance with information contained

herein and with national, state, and local codes and

requirements.

7. DOcontactaqualiedservicetechnicianifa"COREFAIL"

message is displayed on the heater’s control panel.

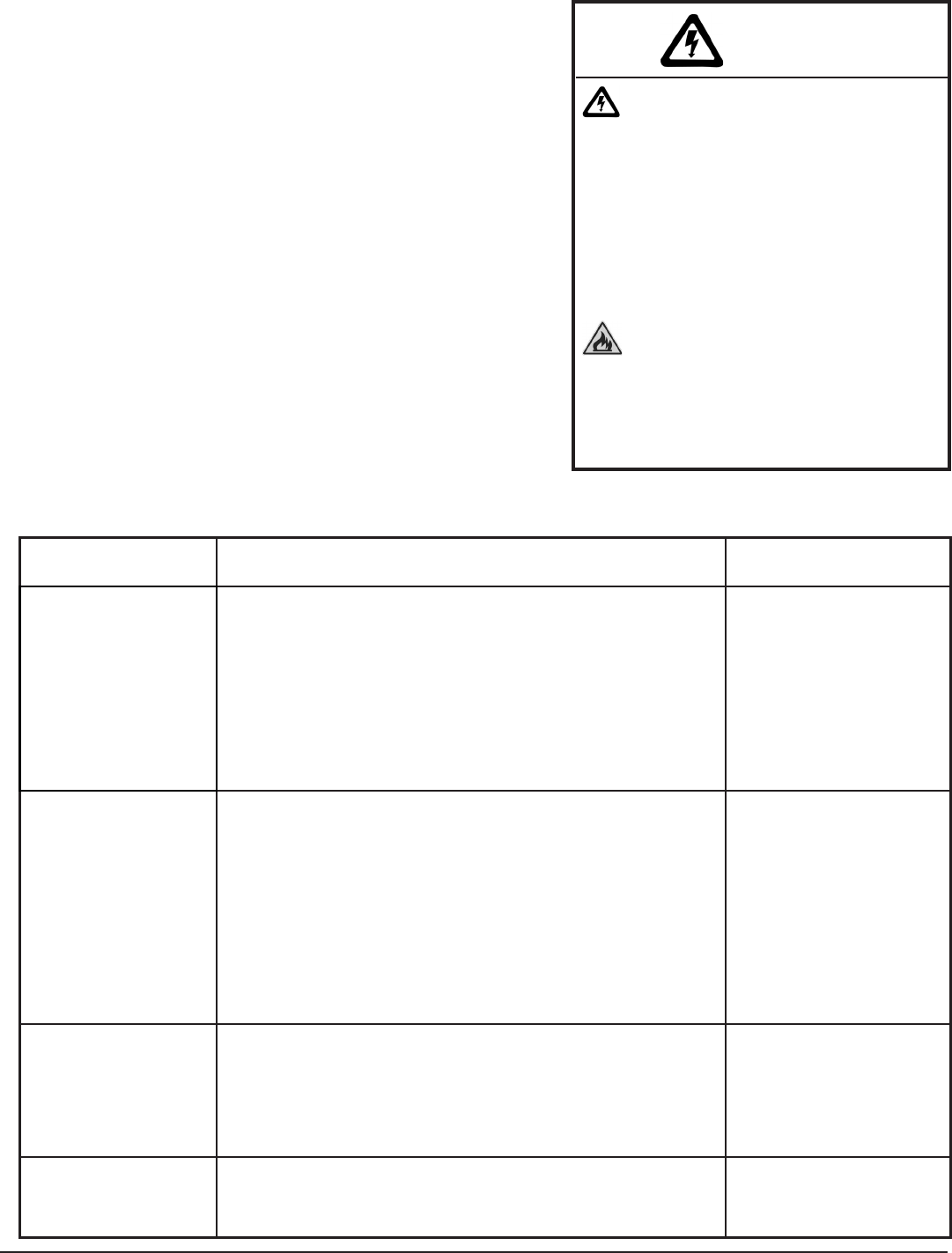

Safety Precautions

2100 Series Safety Information

Built-in Safety Devices

WARNING

Hazardous Voltage: Risk of

electric shock. Can cause injury

or death. This heater may be

connected to more than one

branch circuit. Disconnect power

to all circuits before installing or

servicing. Installation of and/or

service to this equipment MUST

be performed by a qualied

technician.

Risk of re. Can cause injury or

death. Violation of the clearance

requirements can cause improper

operation of the equipment.

Maintain the placement and

clearance requirements specied.

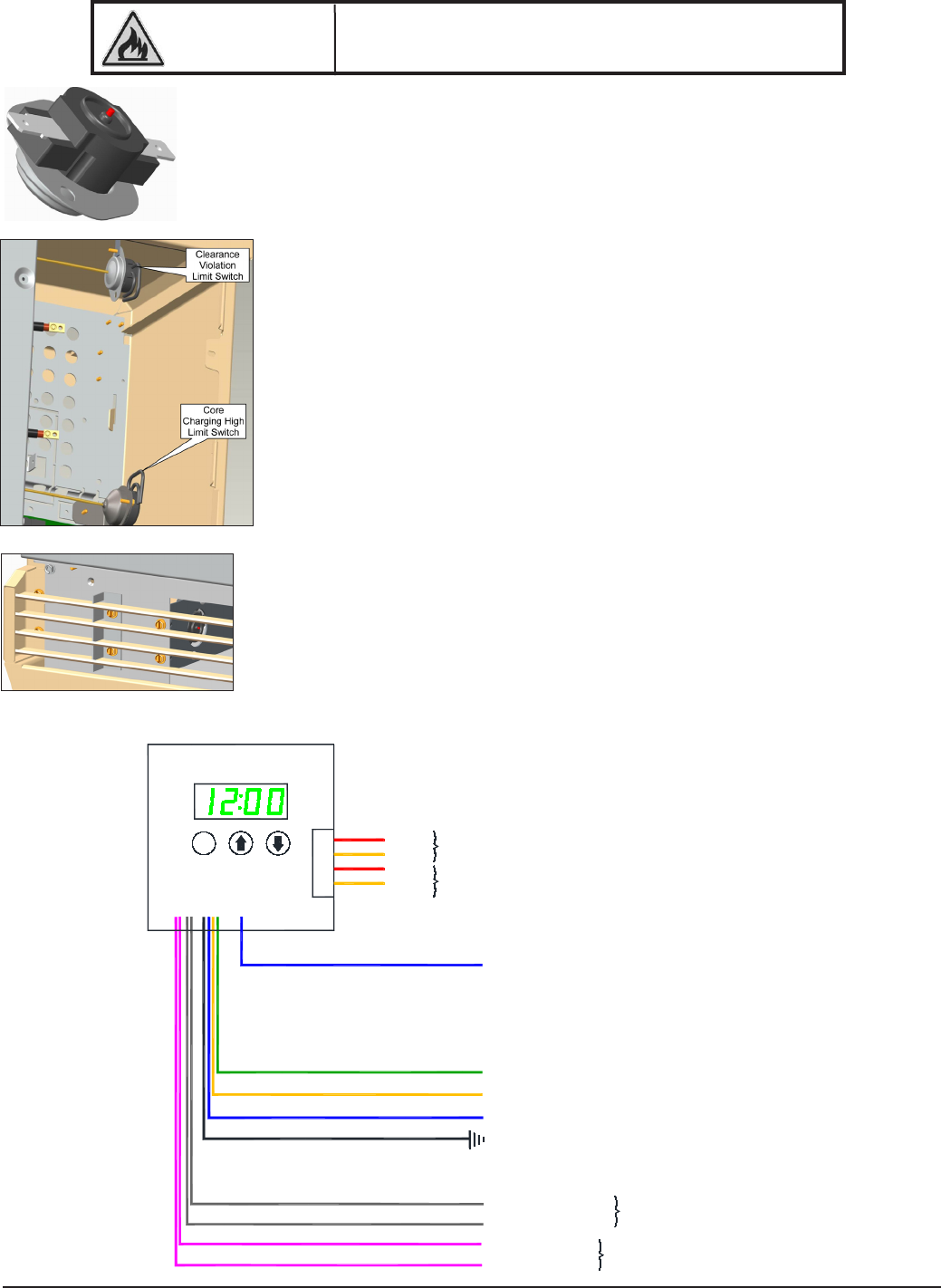

DEVICE NAME FUNCTION LOCATION

ON HEATER

Core Charging High

LimitSwitch

(Manual Reset)

These limits monitor temperature along the back and top

panelsoftheheaterandthebrickcore.Ifnormaloperating

temperature is exceeded, one or both of these switches will

interrupt power to the heating elements and the heater's

controlpanelwilldisplay"COREFAIL".Ifthe"COREFAIL"

message occurs repeatedly, verify heater clearances have

not been violated and that objects have not fallen between

theheaterandthewall.Ifclearancesarecorrect,contacta

service technician.

InsidetheBackPanel

(Extends across the

length of the heater)

Clearance Violation

HighLimitSwitch

(Manual Reset)

InsidetheTopPanel

(Extendsacrossfront

edge)

DischargeAirHigh

LimitSwitch

(Manual Reset)

Monitors discharge air temperature and interrupts power

to the control circuit if normal operating temperature is

exceeded. This limit switch helps protect against the heating

of objects which may obstruct the air discharge area or

violategrillclearances.Ifnormaloperatingtemperatureis

exceeded, this switch will open . When this switch opens,

the discharge air system is disabled and the heater’s control

panel display will no longer illuminate. To reset the system,

pressthemanualresetbuttononthelimitswitch.Ifthe

switch opens repeatedly, verify that grill clearances are not

violated.Ifcorrect,contactaservicetechnician.

Insidethe

AirDischarge

Compartment

(Grill Area)

Tip Over Switch

(Heaters equipped with a

security base only.)

(Auto Reset)

Iftheheaterisnotintheuprightposition,thisswitch

interrupts power to the heating elements and the blower.

This prevents the heater from storing heat in or discharging

heat from the brick core.

InsidetheElectrical

Compartment

(Mounted on the Back Panel

to the Left of the Relay Board)

PowerIndicatorLight The power indicator light indicates that power is being

applied to the heater. Disconnect power to all circuits

before installing and/or servicing this equipment.

LowerRightCorner

(2100 Series Plug-In

Heaters Only)

Operation

General Operation ................................................................................................................................................. 1.01

ControlPanel ...........................................................................................................................................................1.01

RoomTemperatureControl ..................................................................................................................................1.02

Starting the System.................................................................................................................................................1.02

BrickCoreChargeControl .....................................................................................................................................1.02

AutomaticChargeControl ..............................................................................................................................1.02

Manual Charge Control ...................................................................................................................................1.02

Charge Control Override ........................................................................................................................................1.03

Maintenance and Cleaning .................................................................................................................................... 1.03

Installation

ShippingandPackaging ......................................................................................................................................... 2.01

Placement ................................................................................................................................................................ 2.02

ClearanceRequirements ........................................................................................................................................2.02

InitialSet-Up ............................................................................................................................................................2.03

Securing the Heater ................................................................................................................................................2.03

WallSupportBracket ....................................................................................................................................... 2.03

SecurityBase ....................................................................................................................................................2.03

LineVoltageElectricalConnections ......................................................................................................................2.04

DirectWiredRoomHeatingUnits ......................................................................................................... 2.04-2.05

CordConnected(Plug-In)RoomHeatingUnits ............................................................................................2.05

LowVoltageElectricalConnections-PeakControl ............................................................................................2.06

PowerLineCarrier(PLC)PeakControl ..........................................................................................................2.06

LowVoltageDirectWiredPeakControl ........................................................................................................2.07

TimeClockModulePeakControl ...................................................................................................................2.08

LineVoltagePeakControl ............................................................................................................................... 2.08

LowVoltageElectricalConnections-OutdoorTemperatureSensor(Optional) .............................................2.08

BrickLoading ........................................................................................................................................................... 2.09

CongurationMenu ...............................................................................................................................................2.10

Installer'sFinalCheck-OutProcedure ..................................................................................................................2.11

Appendix

Specications ...........................................................................................................................................................A.01

PartsDiagram .........................................................................................................................................................A.02

PartsList...................................................................................................................................................................A.03

InternalLineVoltageWiringDiagrams .................................................................................................................A.04

ManualResetLimitControls .................................................................................................................................A.05

InternalLowVoltageWiringDiagram ...................................................................................................................A.05

Help Menu ...............................................................................................................................................................A.06

ErrorCodes .....................................................................................................................................................A.06-A.07

HingingtheRightSidePanel .................................................................................................................................A.08

Glossary ...................................................................................................................................................................A.09

Warranty

Table of Contents 2100 Series

Table of Contents

TC

A

M

M

P

M

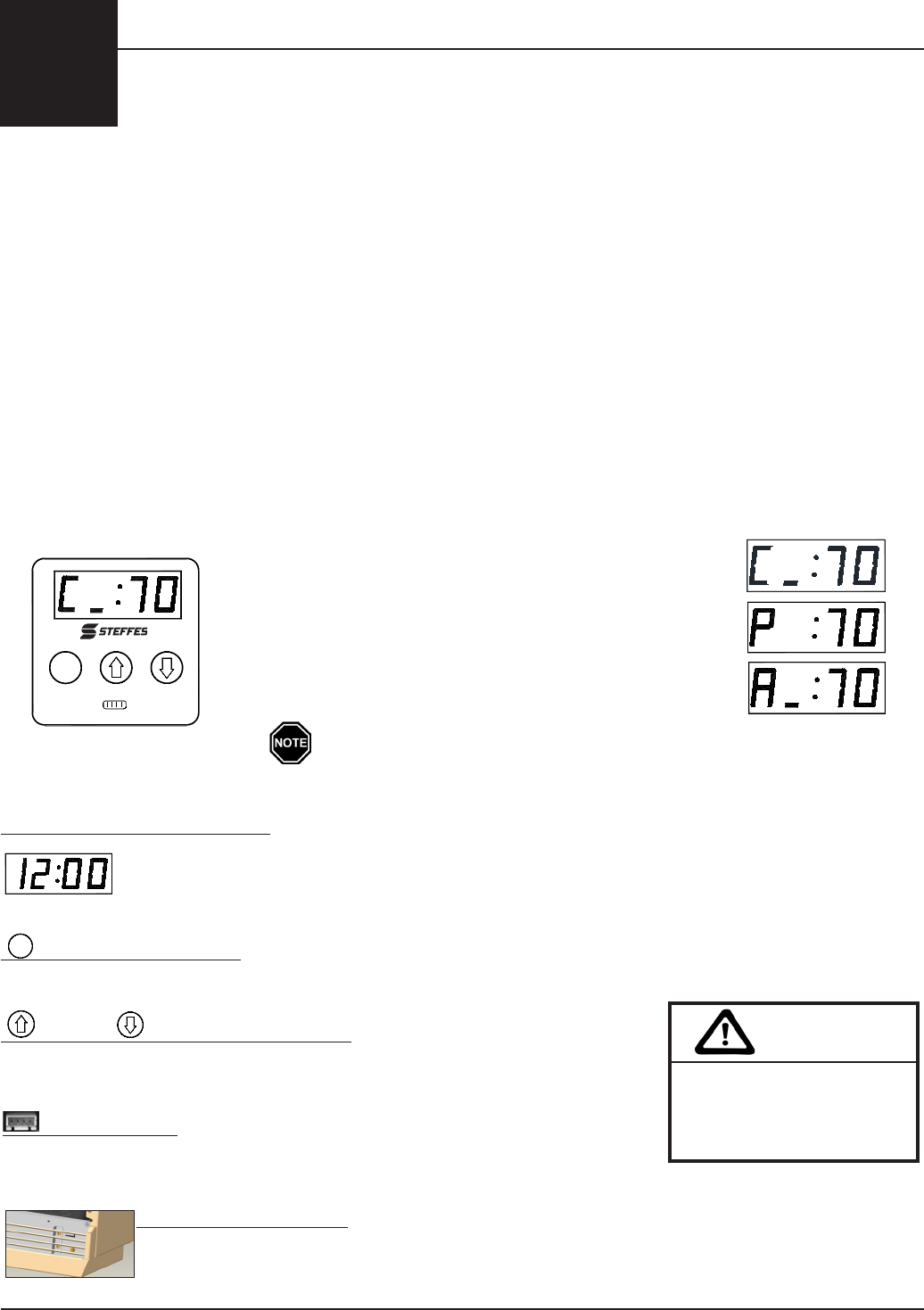

C = Chargeperiodoro-peaktime.

P = Peakperiodoron-peaktime.

A = Anticipatedpeakperiodorpre-peaktime.

(SpecialtyApplicationsOnly)

GENERAL OPERATION

SteesETSroomheatingunitsutilizeo-peakelectricityavailableduringthosetimesofthedayor

nightwhenthePowerCompanycansupplyelectricitymoreeconomically.Duringo-peakhours,

the room heating unit converts electricity to heat and stores the heat in its ceramic brick core. The

heater stores heat at varying levels depending upon outdoor temperature, owner preference, utility

peak conditions, and the requirements of the space being heated.

Asmallamountofheatisradiatedthroughtheheater’scabinet;however,mostoftheheatingis

accomplished by a thermostatically controlled blower. When the room temperature sensor senses a

temperature below the room temperature set point, the blower circulates room air through the brick

core. This air is heated and discharged back into the room to maintain a constant, comfortable room

temperature.

CONTROL PANEL

Alloperationalfunctionsoftheheaterarestoredinamicroprocessorandaccessedthroughthe

controlpanel.(SeeFigure1.)Generally,theuserwillonlyneedtousethispaneltoadjusttheroom

temperature.

ThefourdigitLEDdisplaysspecicoperatinginformation.Instandardoperation,thesedigits

continuously display current room temperature and one of the following brick core operating modes:

Operation

1

2100 Series Operation 1.01

Control Panel - Figure 1

A bar illuminates on the lower portion of the display's second

digit whenever the heating elements are energized.

AM and PM Indicator Lights

TheAMandPMindicatorlightsareonlyutilizediftheSteesTimeClockModuleis

being installed. With this module installed, the system displays time in 12 hour format

andthelightcorrespondingtoeitherAMorPMwillash.Thesystemcanbecongured

todisplaymilitarytime,inwhichcaseboththeAMandPMlightsilluminate.

Mode (EDIT) Button

Activatestheeditingmenuforchangingtheoperatinginformationoftheheater.

Up and Down Arrow Buttons

Increaseordecreaseroomtemperaturesetpoint.Alsousedtoscrollup

or down when viewing or changing the heater's operating functions.

Interface Port

FOR SERVICE USE ONLY! Allowstechnicianexternalaccessforupdating

software and troubleshooting.

Power Indicator Light

The power indicator light indicates that power is being applied to the heater. Discon-

nect power to all circuits before installing and/or servicing this equipment.

CAUTION

Editing operating

information may alter

the performance and

operation of the system.

P

M

M

A

P

M

M

A

P

M

M

A

M

P

A

M

M

ROOM TEMPERATURE CONTROL

The room temperature set point is adjusted by pressing the up arrow to increase or the down

arrow to decrease the set point. When the heater senses a heat call, the variable speed blower is

energized and circulates room air through the brick core. This heated air is discharged into the room

tomaintainthedesiredtemperature.Inaneorttokeeptheroomtemperatureconstant,theblower

automatically adjusts to the appropriate speed and may continue to operate after the set point has

been reached.

Iftheownerpreferstomonitorroomtemperatureatapointawayfromtheheater,anoptional

remoteroomtemperaturesensorisavailable.Aremoteroomsensoralsoprovidesmoreeven

heatdistributioninanareawheremorethanoneheaterisinstalled.Itisrecommendedtousethe

optionalremoteroomsensorinapplicationswheretherightsidepanelhaslessthana12"clearance

or where the right side of the heater is exposed to abnormal temperature conditions such as drafts

from a door or window.

STARTING THE SYSTEM

Onstart-up,odorsand/orsmallvolumesofsmokerelatingtorsttimeoperationoftheheating

components may occur. There also may be an odor associated with dust accumulation if the heater

isshutdownforanextendedperiodoftime.Allowtheheatertochargetoitshighestheatstorage

level(fullcorecharge)toexpeltheseodors.Referalsotomaintenanceandcleaningsectionofthis

manual.

Turningtheheater"OFF"suspendsallfunctionsoftheheater.Toturntheheater"OFF",usethe

downarrowtodecreasetheroomtemperaturesetpointuntil"OFF"isdisplayedonthefaceplate.

Toturntheheater"ON",usetheuparrowtoadjustroomtemperaturesetpointtothedesired

temperature.

The heater MUST remain "ON" if being used to supply a peak control signal to other

controlled loads.

BRICK CORE CHARGE CONTROL

The amount of heat stored in the heater’s brick core can be regulated by automatic or manual charge

control.Theheaterisfactorypresetforautomaticchargecontrolregulation.Ifmanualcharge

controlisdesired,theheatermustbereconguredatthetimeofinstallation.

AUTOMATIC CHARGE CONTROL

With automatic charge control, the brick core charge level is regulated automatically in relation

tooutdoortemperatureandtheheatingrequirements.AnoptionaloutdoorsensororStees

powerlinecarrier(PLC)systemisrequired.TheoutdoorsensororPLCsystemmonitorsoutdoor

temperature and provides this information to the heater. The heater responds by storing heat in the

brickcoreaccordingly.Nouserinterfaceisrequiredtoadjustthebrickcorechargelevel.

MANUAL CHARGE CONTROL

Ifmanualchargecontrolisbeingused,thebrickcorechargelevelmustberegulatedbytheuser.

During the heating season, the user needs to periodically adjust the brick core charge level setting in

relationtooutdoortemperatureandtheheatingrequirementsofthearea.Toconguretheheater

formanualchargecontrol,refertotheCongurationMenu(Page2.10).

Adjusting the Brick Core Charge Level (Manual Charge Control)

Step 1 PressandreleasetheM buttonuntil"CORE"isdisplayed.

Step 2 Presstheuporthedownarrowbuttontoadjustthebrickcorechargelevelsetpoint.The

charge level to be targeted can be set to any value from 0 to 100 percent.

Step 3 Once the desired charge level is set, press the M button once to return to normal display

mode.

Operation 1.02 2100 Series

2100 Series Operation 1.03

CHARGE CONTROL OVERRIDE

The heater is equipped with a charge control override feature that allows the user to force the heater

totargetafullcorechargelevel.Thisoverridecanbeinitiatedorcancelledatanytime.Ifanoverride

isinitiated,theheatertargetsafullcorechargelevelduringthenexto-peakperiod.Itcontinues

tochargeduringo-peakhoursuntiltheheaterachievesfull(maximum)corechargeoruntilthe

override is cancelled. Once full charge is achieved or the override is cancelled, the heater charges

accordingtoitsstandardconguration.

Initiate the Charge Control Override

Step 1 PressandholdtheM, the up arrow, and the down arrow buttons at the same time.

Step 2 Thefaceplatedisplaywillash“FULL”and“ON”.Continuetoholdallthreebuttonsuntil

“ON”displayscontinuouslyonthefaceplate.

Step 3 Releasethebuttons.Theoverrideisnowenabled.Thefaceplatewillreturntodisplayingits

standard operating mode.

Cancel the Charge Control Override

Step 1 PressandholdtheM, the up arrow, and the down arrow buttons at the same time.

Step 2 Thefaceplatedisplaywillash“FULL”and“OFF”.Continuetoholdallthreebuttonsuntil

“OFF”displayscontinuouslyonthefaceplate.

Step 3 Releasethebuttons.Theoverrideisnowcancelled.Thefaceplatewillreturntodisplaying

its standard operating mode.

MAINTENANCE AND CLEANING

Aswithmostheatingsystems,airborneparticlesandodorsin

the room may be drawn into the heating system and oxidized.

Since the room air passes directly through the hot brick core of

theETSheater,theoxidationprocesswillchangetheproperties

of these particles and odors. Odors can be amplied; thus, it is

recommended not to operate the heating system if odors such

as those from paints, varnishes, or chemicals are present in

the air.Allowtheareatobecompletelyairedoutbeforeoperating

the heater.

Asforairborneparticles,aftertheyhavebeenoxidizedtheyare

expelled back into the room and may accumulate on the heater or other surfaces. Over time, these

particles may appear as a black residue, commonly referred to as soot. High concentrations of air

borne particles from such things as aerosols, dust, candles, incense, pet hair, high humidity, smoke,

or cooking can contribute to poor indoor air quality and accelerate this process. To minimize the

blackresiduebuild-up,cleantheoutersurfaceoftheheateronaregularbasis.Washthecabinet,

only when cool, with a nonabrasive household cleaner. Do not use scouring powders or furniture

polish.Steesrecommendsusing"SoftScrubwithBleach"brandcleanseroranequal.

Regularlyvacuumaroundallsidesoftheheater.Checkthebackoftheheatertomakesureno

objects have fallen behind it and the grill area to make sure there isn't anything obstructing air

ow.Checkallsidesoftheheatertobesuretherequiredclearancesarenotbeingviolated.Objects

should never be placed on top of the heater.

Noadditionalroutinemaintenanceisrequired;however,havingaprofessionalservicetechnicianclean

the blower periodically will decrease the likelihood of undesirable blower noise due to dust accumulation.

No heater panel, with the exception of the painted front panel and painted right side panel, can

ever be removed from the heater. Should any other exterior panel(s) be removed, the heater must

be taken out of service permanently. All panels must be in place when operating the heater.

Risk of re. Can cause injury

or death. Violation of the

clearance requirements can

cause improper operation

of the equipment. Maintain

the placement and clearance

requirements specied.

WARNING

Installation

2

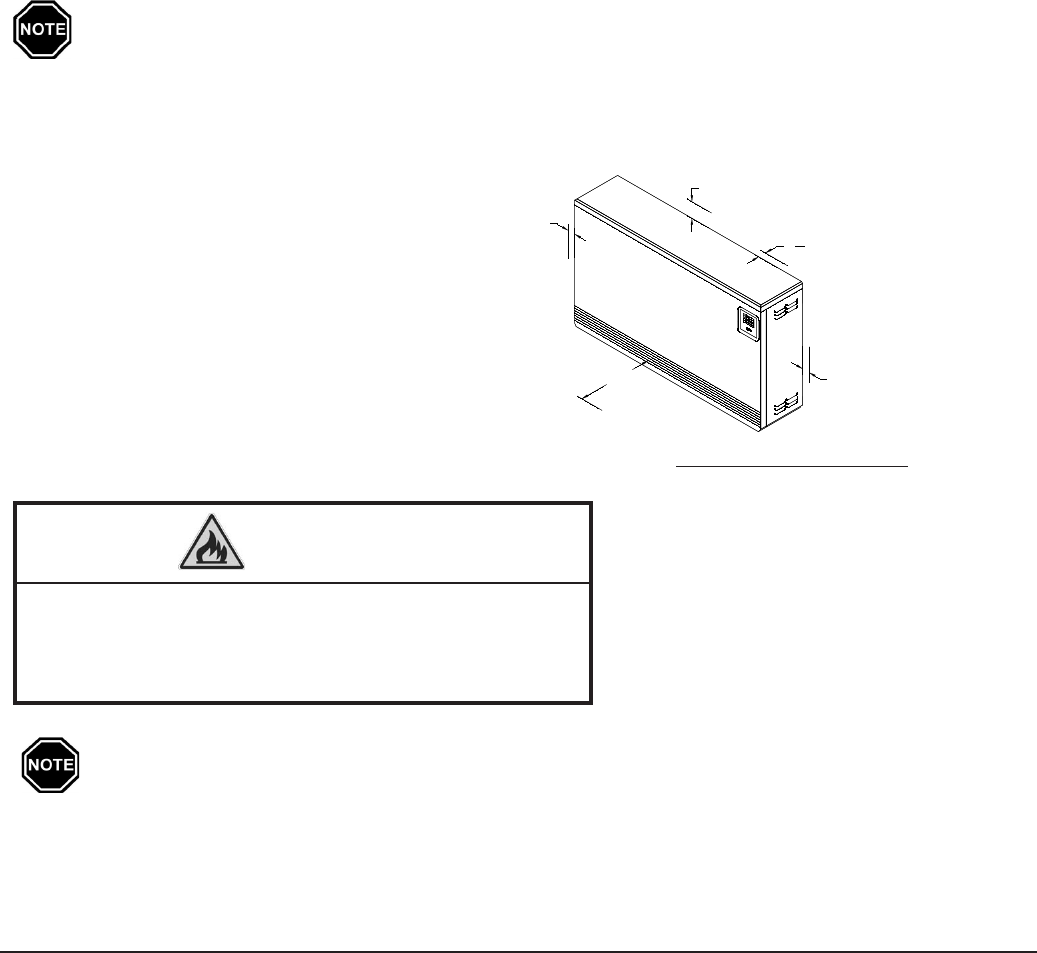

SHIPPING AND PACKAGING

The heater should always be transported in an upright

position to avoid damage to internal components and

insulation materials. The items shipped with each heater

include the following:

WALL SUPPORT BRACKET

(placed on shipping pallet un-

der heater...used in all heaters

except plug-in models)

SECURITY BASE

or

(packaged in heater

box on back side...

used only in plug-in

models)

Installation 2.01 2100 Series

(shipped inside the box on

top of heater )

CAUTION

Risk of personal injury. Steel

edges can cut. Use caution when

installing or servicing equipment.

3

or

BOXES OF CERAMIC BRICK

(shipped separately and

packaged 2 bricks per

package)

1

2102 8 pkgs

2103 12 pkgs

2104 16 pkgs

2105 20 pkgs

2106 24 pkgs

2102plug-in

MODEL

BRICK

INFORMATION PACKAGE

(includes Owner's Manual, Warranty

Registration Card, and Brick Installation Tool)

2

MOUNTING HARDWARE PACKAGE

(shipped inside heater's

electrical compartment...used in all

heaters except plug-in models)

4

SECURITY BASE KIT

(shipped inside heater's

electrical compartment...

used only in plug-in models)

8 pkgs

CLEARANCE REQUIREMENTS

There are minimum clearances that must be

maintained when choosing a location. (See

Figure2.)Theseareassurroundingtheheater

must be kept open and free of debris. Objects

such as curtains, furniture, or bed covers must

bekeptaminimumof4"fromallsurfacesofthe

heater. The back clearance is provided by the

wall mounting bracket or by the security base.

DONOTplaceobjectsofanykindontopofthe

heater.Theheatermayberecessedintoawall;

however, access to the heater's front panel and

grillMUSTNOTbeobstructedorenclosedandall

clearancerequirementsMUSTbemaintained.

2100 Series Installation 2.02

PLACEMENT

Theheatercanbeplacedonaninteriororanexteriorwall.Idealplacementisalonganinteriorwall,

adjacenttoanexteriorwall.Tondthebestlocationfortheheater,considerthefollowing:

• Physical Dimensions-AllclearancerequirementsspeciedintheClearanceRequirements

section(Page2.02)MUSTbefollowedtoensureproperoperation,safety,andperformanceofthe

equipment.

• Weight-TheweightoftheheaterMUSTbeconsideredwhenselectingalocation.Ifthereare

structural weight concerns, consult a building contractor or architect before installing.

• Flooring-Theheatercangenerallybeplacedonanystandardooring.Thebottomoftheheater

willbewarminnormaloperation;therefore,discolorationundertheheatermayoccurtocertain

ooringproducts.ContacttheooringmanufacturerorSteesCorporationwithquestions

regardingtheacceptabilityoftheoorcovering.Ifinstallingonextremelythickcarpet,itmaybe

necessary to slightly elevate the heater as carpet should remain at least ¾ inch away from air

discharge grill openings.

• Room Temperature Sensing -Toensureaccurateroomtemperaturesensing,avoidinstalling

theheaternearanopenstairwell,nearsourcesofheatorcold,orwithlessthan12"clearanceon

therightside.RefertoRoomTemperatureControlsection(Page1.02)forinformationregarding

the optional remote room temperature sensor.

Risk of re. Can cause injury or death.

Violation of the clearance requirements can cause

improper operation of the equipment. Maintain the

placement and clearance requirements specied.

WARNING

A clearance of 12" is recommended on the right side of heater. If there is less than a

12" clearance, a remote room temperature sensor is recommended to ensure accu-

rate room temperature sensing. The 12" clearance also allows space for hinging the

right side panel open for servicing.

Special requirements must be considered if placing the system in a garage or other

area where combustible vapors may be present. Consult local, state, and national

codes and regulations to ensure proper installation.

Minimum Clearances

Top 4"

Front&Grill 15"

Sides 2"

Back 11/2"

Minimum Clearances

Figure 2

1

1

2

"

15"

2"

4"

2"

(12" Recommended)

WARNING

Risk of re. Can cause injury or death. Failure to secure the heater can cause

the heater to fall over. Properly secure the heater by using the wall support

bracket to mount it to the wall or by installing the security base.

Installation 2.03 2100 Series

INITIAL SET-UP

Step 1 Unboxtheheaterandliftitotheshippingpallet.Placetheshippingboxasideuntilthe

brickloadingprocess(Page2.09).

Step 2 Placetheheaterinthedesiredlocationandcheckforproperclearancesonallsides.

Step 3 Removethescrewsattheloweredgeofthepaintedfrontpanel.

Step 4 Pulltheloweredgeofthepanelforwardandunhookitfromthetoppanel.Carefullyplace

the painted front panel aside to avoid damage.

No heater panel, with the exception of the painted front panel and painted right side panel, can

ever be removed from the heater. Should any other exterior panel(s) be removed, the heater must

be taken out of service permanently. All panels must be in place when operating the heater.

SECURING THE HEATER

The2100seriesroomheatingunitMUSTbesecuredforsafetypurposes.Adirectwiredheaterissecured

withawallsupportbracket,whileaplug-inheaterissecuredwithasecuritybase.

WALL SUPPORT BRACKET

Step 1 Removethemountinghardwarepackagefromits

shipping position inside the electrical compartment.

Step 2 Placethetopofthewallsupportbracket231/2"

fromtheoorandsecureittothewallwiththelag

boltsprovided.ThebracketMUSTbemountedso

thelagboltssecureintowoodwallstuds.Ifthewall

is not a standard wood studded structure, alternate

fasteners must be used.

Step 3 Attachthewallsupportclipstothebackofthe

heater.

Step 4 Set the carriage bolts aside as they will be used to

attach the heater to the wall support bracket after

theeldwiringconnectionsaremade.

SECURITY BASE

120Vplug-incordmodelscomeequippedwithasecuritybase.Thisbasemustbeattachedtothebottom

paneloftheroomheatingunit.Itispackagedinsidetheshippingboxonthebacksideoftheheater.

Step 1 Removethesecuritybasemountinghardwarepackagefromitsshippingpositioninsidethe

electrical compartment.

Step 2 Gentlylaytheheateronitsback.Foreaseofinstallation,slightlyelevatethebottomoftheheater.

Step 3 Aligntheholesinthesecuritybasewiththepre-drilledholesinthebottomoftheheater.

Usingthesix#14x1¼"sheetmetalscrewsandwashersprovidedinthemountinghardware

package, attach the security base to the painted bottom panel.

The angled corners of the security base will be towards the front of the heater

and the painted side of the security base faces up.

Step 4 Afterthebaseisattached,returntheheatertoitsuprightpositionandplaceindesired

location.DONOTenergizetheheateruntilinstallationiscomplete.

Wall Support Bracket Mounting

Figure 3

wall support

clip

attached to studs

lag bolts

23 1/2"

floor

carriage

bolt

wall support bracket

LINE VOLTAGE ELECTRICAL CONNECTIONS

Steesroomheatingunitsareavailableforconnectionto

variousinputvoltages.Standardcongurationfordirectwired

heatersis240V;cord-connectedheatersareconguredtoplug

intoa120Vwalloutlet.Todeterminethecongurationofthe

heater,refertotheUnitIdenticationLabelonthelowerleft

sidepanel.(SeeFigure4.)AllheatersareULandcULsafety

listed.

DIRECT WIRED ROOM HEATING UNITS

Instandardconguration,thechargingcircuitoftheheateriswiredforconnectionto240V/208V.

Ifconnectingto208V,theheaterwilloperateat75%ofitsratedwattage.Theblowerandcontrols

circuitintheheaterisconguredfor240V.Ifthecontrolcircuitistobeconnectedto120Vor208V,

contact the factory.

208V SYSTEMS ONLY:

Instandardconguration,Steesheatersaredualratedfor240Vand208Vpowerconnections.The

heatersarefactoryconguredfor240V.Ifthecontrolcircuitisoperatingon208Vpower,thevalue

inLocation16(L016)mustbechangedto210andthevalueinLocation28(L028)mustbechanged

toavalueof5forheatersequippedwithFascoblowerand10forP-Techblower.

Field Connection Wire and Circuit Breaker Sizing Guide

All2100seriesheatersareequippedwithatwo-circuitelementfeedoptionandafan/controlcircuit

(Figure5onpage2.05).RefertotheUnitIdenticationLabelforpropersizingofeachcircuit.Ifsingle-

feedconnectionisused,sizethecircuitfortotalwattage.(ChargeCrct#1+ChargeCrct#2+Fan/Cntrl

Crct = Total Wattage.)

2100 Series Installation 2.04

Sample Unit Identication Label

Figure 4

HAZARDOUS VOLTAGE:

Risk of electric shock. Can

cause injury or death. DO

NOT energize the heater until

installation is complete. Equip-

ment must be installed by a

qualied technician in accor-

dance with applicable local,

state, and national codes and

regulations.

WARNING

Usecopperwireratedat75

o

C minimum only.

This eld connection wire and breaker size guide reects only the code interpretation

of Stees. It is the responsibility of the installer to comply with all applicable codes

and regulations.

Maximum kW

Wire Size 240 VAC 277 VAC 208 VAC

Maximum Curcuit

Breaker Size

#14AWG 2.8 3.3 2.4 15

#12AWG 3.8 4.4 3.3 20

#10AWG 5.7 6.6 4.9 30

#8AWG 7.6 8.8 6.6 40

#6AWG 11.5 13.2 9.9 60

Field Wiring

Step 1 Afterestablishingplacementoftheheater,mount

aeldconnectionjunctionboxinalocationwhere

heater-to-eldwiringconnectionscanbemadeeasily.

The junction box can be located beside the heater,

behindtheheater,ormountedintheoorbelowthe

heater.Steesrecommendsasteeljunctionboxto

provide protection against overheating.

The junction box MUST remain accessible for

future service to the heater and MUST be sized

in accordance with all applicable electrical

codes and regulations.

Step 2 Routethepropersizeandtypeofwiringfromthebreakerpaneltotheeldconnection

junction box.

Step 3 Connecttheeldwiringtothewiringharness(umbilicalcord)oftheheaterinsidethe

junction box.

Step 4 Removetheorangebreakerpanellabelfromthemountinghardwarepackage.Thislabel

MUSTbeappliedintheelectricalservice(breaker)panelandmarkedaccordinglytoidentify

the branch circuits feeding the room heating unit.

Installation 2.05 2100 Series

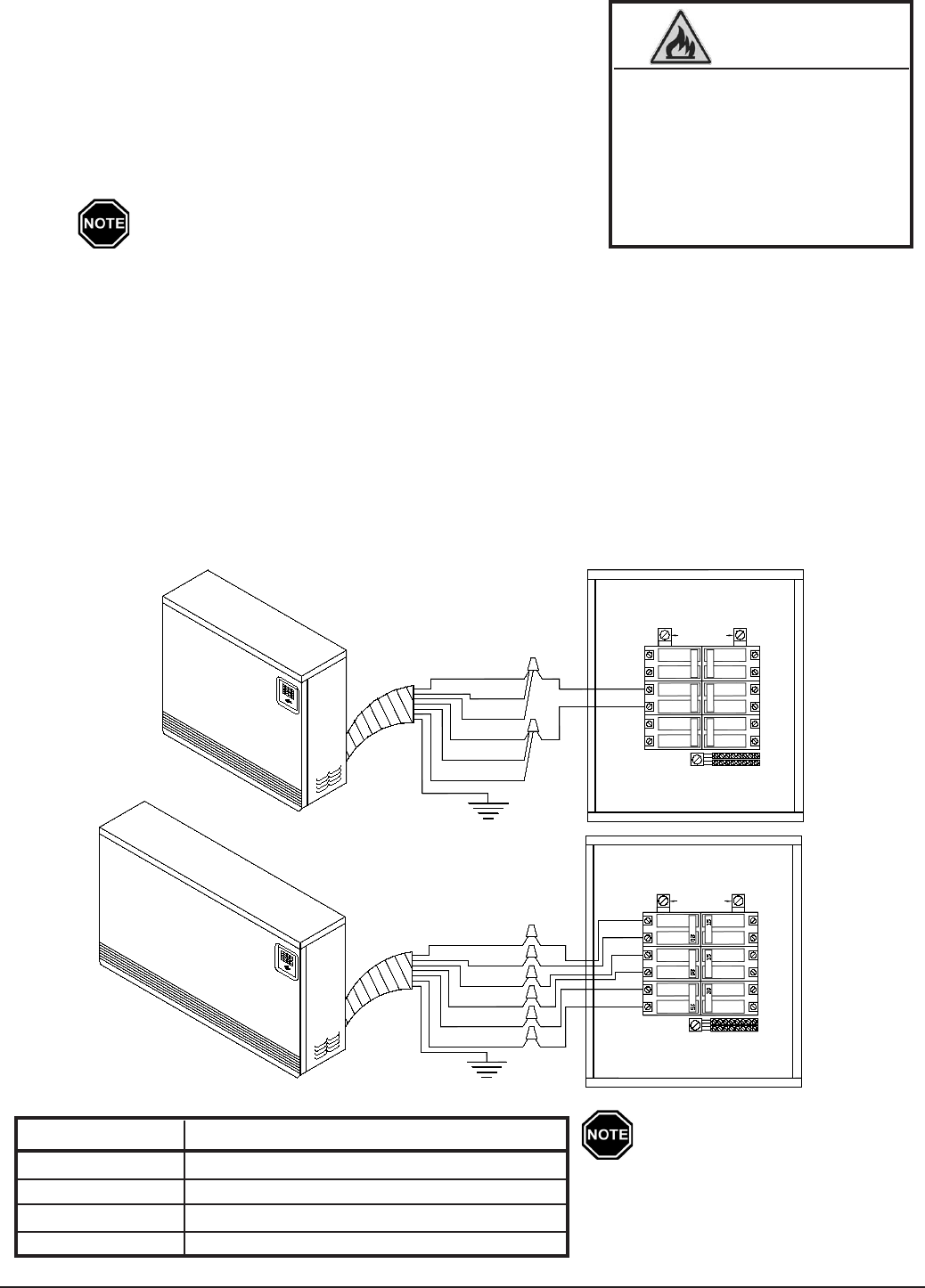

Typical System Wiring Diagram

Figure 5

Risk of injury or re. Poor

or marginal electrical

connections will cause the

connection to overheat and

fail. Use extreme caution

when making all electrical

connections.

WARNING

Wiring Harness (Umbilical Cord ) Color Code Chart

WIRE COLOR CIRCUIT DESCRIPTION

Black Circuitfeedfortwoofthefourheatingelements

Red Circuitfeedfortwoofthefourheatingelements

BlueandBlue/Black Circuitfeedfortheblowerandheater'scontrol

Green Ground

Connections shown are for

systems with a 240V/208V

blower/control circuit. Re-

fer to the Unit Identication

Label on the lower left side

panel of the heater for proper

voltage conguration.

RED

RED

BLACK

BLUE/BLACK

GREEN

3

15

30

6

BLACK

BLUE

CIRCUIT

SINGLE

CONNECTED

BREAKER PANEL

4

1

2

20

15

5

20

15

240VAC SOURCE

GREEN

MULTIPLE

CONNECTED

CIRCUIT

4

240VAC SOURCE

BREAKER PANEL

BLACK

BLUE/BLACK

BLUE

BLACK

RED

RED

2

3

1

6

5

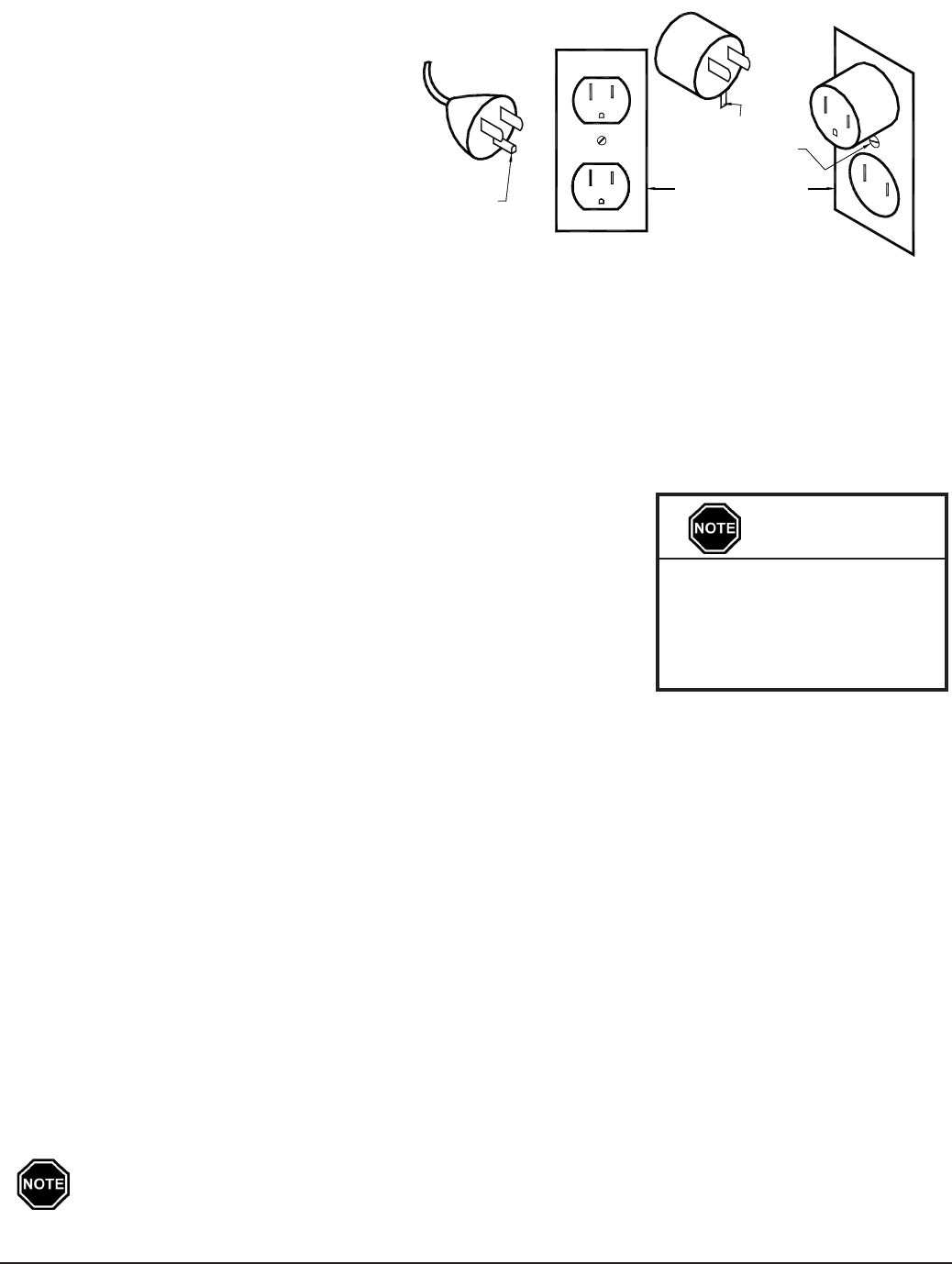

CORD-CONNECTED (PLUG-IN) ROOM HEATING UNITS

All cord-connected heaters are factory-

conguredtobepluggedintoa120Vwall

outlet. The circuit outlet the heater is

plugged into should be designated solely to

the heater for circuit sizing purposes as well

as peak control and metering purposes in

some instances. To determine the correct

circuitsize,refertotheFieldConnection

WireandCircuit Breaker Sizing Guidein

this manual.

120Vcord-connectedroomheatingunits

must only be used with receptacles that are

of the grounding type and suitable for the

loadoftheheater.(SeeFigure6forcord

and receptacle requirements.)

Theroomheater'scordhasaplugasshowninFigure6A.Anadapter,asshowninFigure6B,isavailable

forconnectingthree-bladegroundingtypeplugstotwo-slotreceptacles.Thegreengroundingmeans

extending from the adaptor must be connected to a permanent ground, such as a properly grounded

outletboxasshowninFigure6C.Thisadaptorshouldnotbeusedifathree-slotgroundedreceptacle

is available.

PEAK CONTROL

SteesETSheatingequipmentisgenerallycontrolledbythePower

Company via a peak control signal. This signal can be sent to the

heaterusingtheSteesPowerLineCarriersystem,lowvoltagewiring,

aSteesTime Clock Module, orlinevoltage wiring. In applications

utilizing automatic charge control, outdoor temperature information

is required and can be received via an outdoor sensor or power line

carrier control.

The2100seriesroomheatingunitisfactoryconguredforusewithpowerlinecarriercontrol.Refer

totheCongurationMenu(Page2.10)forinformationonconguringtheheaterfortheapplication.

POWER LINE CARRIER (PLC) PEAK CONTROL

TheoptionalSteesPowerLineCarrier(PLC)controlsystemhastheabilitytocommunicatewiththe

heater through the existing electrical circuits in the structure. With the power line carrier option, hard

wired low voltage connections from the power company's peak signaling switch connect directly to the

transmitting device. The switch signals peak control times to the transmitter, the transmitter sends

the signal to an unlimited number of 2100 series heaters, which receive this information and respond

accordingly.

Inadditiontoprovidingpeakcontrolsignals,thetransmittingdevicealsoprovidesoutdoortemperature

information, room temperature set back, and anticipated peak utility control signals (if applicable).

AsthePLCsystemisoptional,itmustbespeciedatthetimeofordering.IfutilizingaPLCsystem,refer

totheOwner'sandInstaller'smanualaccompanyingthetransmittingdeviceforinformationonthe

installation and operation of the power line carrier control system.

PLC Communication is very reliable in most applications but can be aected and

hindered by connection method used, electrical layout of the application, operation

of other equipment in the same electric system, dirty power, etc. Stees does not

guarantee eective communication of the PLC system in all applications and is not

responsible for any communication issues outside normal operating malfunctions.

2100 Series Installation 2.06

Never install any wiring

in the line voltage

compartment of the 2100

series heater unless it is

rated for line voltage.

IMPORTANT

120V Receptable Requirements

Figure 6

Grounding Screw

Grounding Means

Grounding Pin

(Fig 6A)

3-Slot Grounded

Receptacle

Grounded Outlet

Box (Fig 6C)

Adapter (Fig 6B)

2-Slot Receptacle

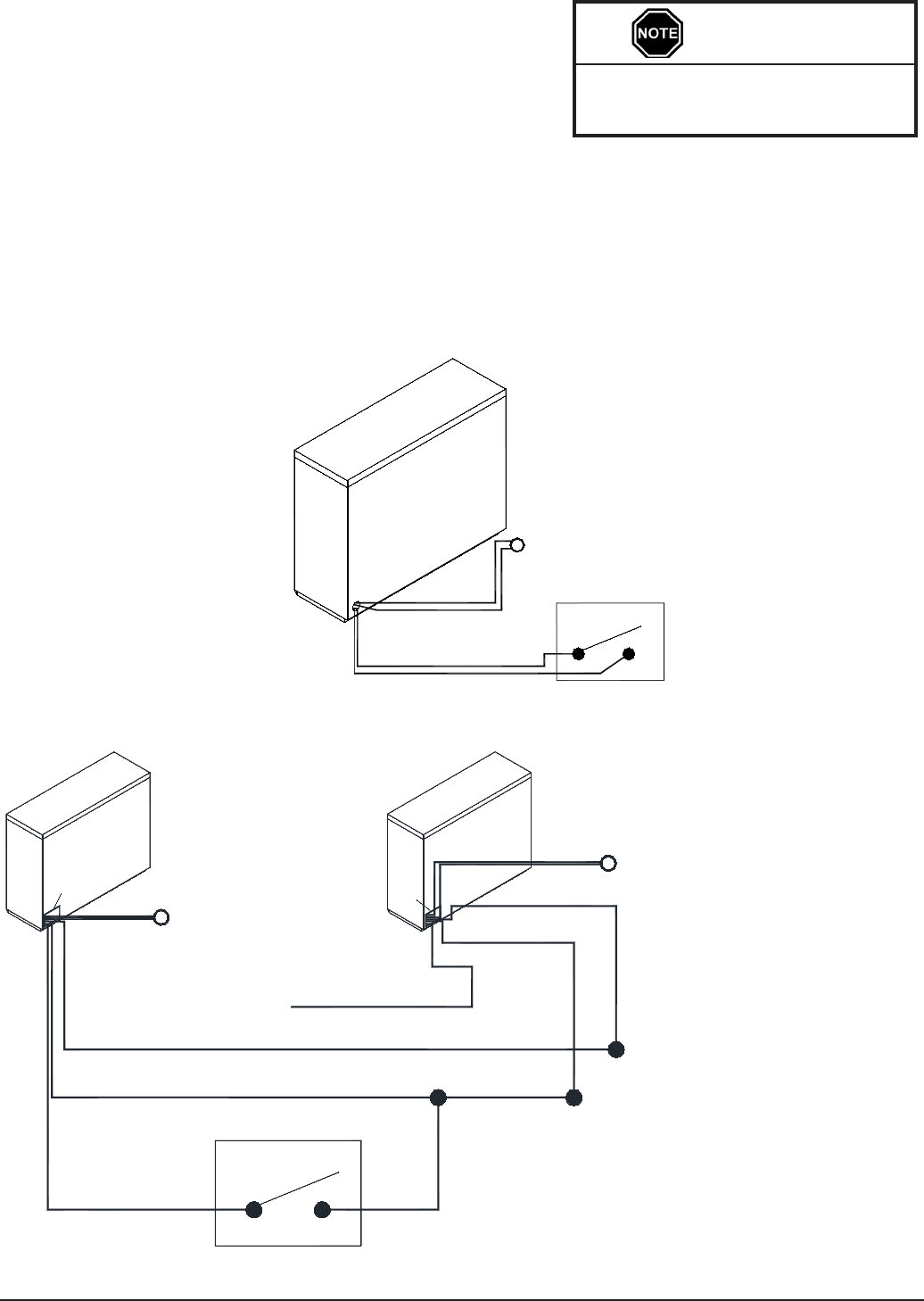

Multiple Unit - Low Voltage Connections Direct Wired Controls

Figure 8

Notes: 1. Connecting the low voltage hot (blue)

wire from multiple heaters to a single

control switch may cause damage to the

system. In multiple heater applications,

connect the wires as shown for proper

operation.

2. In this conguration, one outdoor sensor

is needed for each heater installed.

Installation 2.07 2100 Series

Single Unit - Low Voltage Connections Direct Wired Controls

Figure 7

LOW VOLTAGE DIRECT WIRED PEAK CONTROL

Ifusingthelowvoltagecontroloption,theheaterisdirect

wiredtothepowercompany'speakcontrolswitch.Field

connections from the switch are made to the heater’s low

voltage wiring harness through the low voltage raceway.

These wires are also accessible from inside the electrical

compartment.ClassII(lowvoltage)wiringshouldnever

enter a line voltage area of the heater, including its umbilical cord.

Somepowercompaniesalsouseanticipated(pre-peak)signals.Ifapplicabletoyourinstallation,

thecontrolswitchprovidingthepre-peaksignalcanalsobeconnecteddirectlytotheheaterwith

lowvoltagewire.RefertotheLowVoltageConnectionsDirectWiredControlsDiagram(Figure7)for

reference to peak and anticipated peak low voltage connections.

If routing low voltage wire near line

voltage conductors, shielded wiring

must be used.

IMPORTANT

Control Switch

Peak

Outdoor Sensor

Gray

Gray

Blue/White

Blue

BACK OF

HEATER

BACK OF HEATER

Blue/White (Peak)

Blue (Hot)

Black (Common)

Blue (Not Used)

BACK OF HEATER

Blue/White

Outdoor Sensor

Black

#2

#1

Gray

Gray

Gray

Gray

Peak Control Switch

Outdoor Sensor

(See Note 2)

(See Note 1)

(See Note 2)

Low Voltage

Junction Box

Low

Voltage

Junction

Box

TIME CLOCK MODULE PEAK CONTROL

TheSteestimeclockmodule(OrderItem#1301014)isanotheroption

for providing a peak control signal to the heaters. The optional time

clock module is installed inside the heater’s line voltage electrical

compartment and interfaces with the heater’s relay board. Peak

control times are required to be programmed into the heater once

the module is installed to enable the time clock feature.

Inadditiontoprovidingpeakcontrolsignals,thetimeclockmodule

can also provide automatic room temperature set back, if desired.

Refertotheinstructionsprovidedwiththetimeclockmoduleformore

information on the installation and operation of this device.

LINE VOLTAGE PEAK CONTROL

Linevoltagepeakcontrolisalsoanoption,butisnotthepreferredmethodasitisusuallymorecomplex

andexpensive.Iflinevoltagecontrolisutilized,theblower/controlcircuitoftheheatermustbepowered

withanuninterruptedcircuit.Anexternalswitchingdevice,suchasarelaypanel,isnecessarytodirectly

controltheheatingelementchargingcircuits.Ifrelyingonthismethodofcontrol,thefaceplateonthe

heatermustcontinuouslydisplayabrickcoreoperatingmodeof“C”(charge)regardlessofwhetheritis

ano-peakoron-peaktime.

LOW VOLTAGE ELECTRICAL CONNECTIONS - OUTDOOR TEMPERATURE SENSOR

(OPTIONAL)

The outdoor temperature sensor can be installed in one of two

ways:directwiredtothesystemorwiredtotheSteespower

linecarriersystem.Ifdirectwiredtotheheater,onesensor

perheaterisrequired.RefertotheLowVoltageConnection

Diagrams(Figures7and8)andtheinstructionsincludedwith

the sensor for information on the installation of this device.

Unless servicing, power

to the heater should not

be turned off at the circuit

breaker when using the

Steffes Time Clock Module.

If power is off to the blower/

control circuit for an

extended period of time, it

may be necessary to reset

the current day and time.

IMPORTANT

2100 Series Installation 2.08

Installation Methods: A) Hard wired to the heater

OR

B) ConnectedtoPowerLineCarrier(PLC)-referenceOwner'sandInstaller's

Manual for this installation.

Theory of Operation: The outdoor sensor monitors outdoor temperature and provides this informa-

tion to the system. The system responds by automatically storing heat in its

brick core according to outdoor temperature and the heating requirements.

Location of: The outdoor sensor must be placed in a location where it can accurately sense outdoor

temperatureandisnotaectedbydirectsunlightorotherabnormaltemperaturecondi-

tions.

Wiring to heater:

• Routelowvoltagewirefromtheoutdoorsensortotheelectricalcompartment

through one of the low voltage wire knockouts.

• Connect to the two gray wires in the low voltage raceway.

• Ifthesensorwiringisroutedthroughanexternalwall,theopeningthroughwhich

thewireisroutedMUSTbesealed.Failuretodosomayaecttheaccuracyofthe

outdoor temperature sensor.

• The outdoor sensor can be extended up to a total of 250 ft if needed.

• UnshieldedClassII(thermostat)wirecanbeusedasextensionwireaslongasitis

segregated from any line voltage cabling.

• Nootherloadscanbecontrolledorsuppliedthroughthiscable.Itisforconnection

oftheoutdoorsensorONLY.

• ThislowvoltagecableMUSTnotenteranylinevoltageenclosure.

If connecting to the Steffes power line

carrier (PLC) system, follow the instal-

lation instructions in the PLC system's

Owner's and Installer's Guide.

IMPORTANT

Installation 2.09 2100 Series

Figure 10

Note: Row 8 brick faces down

Row 7

Row 6

Row 5

Row 4

Row 3

Row 2

Row 1

Brick Loading

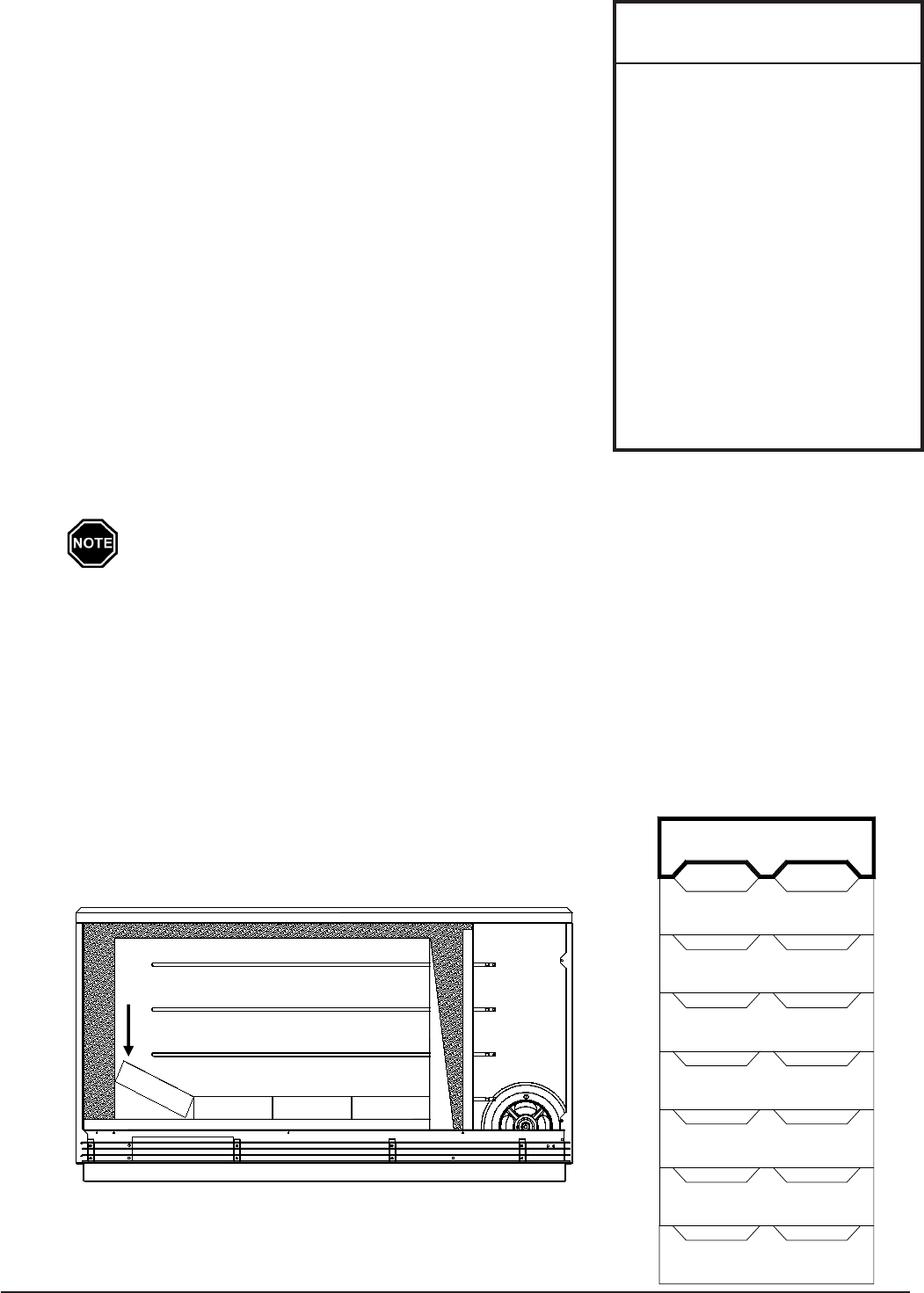

BRICK LOADING

Step 1 Verify that the heater is not energized.

Step 2 Direct Wired Room Heating Units Only-Placetheheater

against the wall support bracket and use the carriage bolts

provided to securely mount the heater to the wall.

Step 3 Placetheshippingboxinfrontoftheheaterbeforeloading

thebricktocatchbrickdebris,toprotecttheooring,and

foreasyclean-upuponcompletionoftheinstallation.

Step 4 Removethescrewsontherightsideofthegalvanized

front panel and rotate the panel to the left to remove.

Step 5 IfinstallingaModel2104,2105,or2106,removeand

discard the cardboard spacer(s) from the brick core.

Step 6 Beginbrickloadingwithrowonebyinstallingtherstbrick

face-upandslidingtothefarrightsideoftheheater's

storagecavity.Besurethegroovedsideofthebrickisup

andtstightagainsttherightairchannelandtheback

insulationpanel.ContinueloadingthebricksforRow1

asshowninFigure9.Theinsulationontheleftsidemay

need to be compressed to install the last brick on each row.

To compress the side, squeeze the inner panel towards the outer panel as shown

in Figure 9 below.

Step 7 Continuethebrickloadingprocessonerowatatime.Allbricksinrowsonethroughseven

mustbeloadedwiththegroovedsideup.(SeeFigure10.)

Step 8 Installtheeighth(top)rowofbrickswiththegroovedsideofthebricksfacingdown.(See

Figure10.)A3"x11"metalbrickinstallationtoolisenclosedintheinformationpackageto

assistwithloadingthetoprowofbrick.Laythemetaltooloverthefarrightbrickinrow7.

Slideabrickoverthemetalpieceandintoposition.Pullthemetalpieceout.Continuethis

procedure until the entire top row of brick is installed.

Step 9 Once all bricks are loaded, replace the galvanized front panel.

Brick Placement

Figure 9

The heater MUST be securely

mounted to the wall or to its

security base prior to brick

loading.

To properly seal the brick

core, make sure all bricks are

installed correctly.

Install bricks carefully to

avoid damage to the bottom

and back insulation panels of

the storage cavity.

Maintain an even horizontal

line across the brick core

during brick installation so

air ow through the heater

is not obstructed.

IMPORTANT

4

3 2 1

CONFIGURATION MENU

Stees2100SeriesroomheatingunitshaveaCongurationMenu

which allows them to be customized to the power company and

consumer’sneeds.Thismenucanbeaccessedonstart-upandallows

congurationsettingstobeadjusted.

Accessing the Conguration Menu

Step 1 Energizeheater.AccesstoCongurationMenuisallowed

forrsttwo(2)minutes of operation. Ifheaterhasbeen

energizedforovertwo(2)minutes,itmustbepoweredoandbackonagain.

Step 2 PressandreleasetheMbuttonuntilthefaceplatedisplays“CONF”.

Step 3 Presstheuparrowonceandthefaceplatewilldisplay“C000”.Thedisplaywillashbetween

“C000”andthecorrespondingcongurationvalue.

Step 4 Ifnecessary,editthecongurationbypressingandholdingtheM button while using the up

or the down arrow button to change the value.

Step 5 Once the value is correct, release the buttons and press the up arrow button to go to the next

conguration(C001,C002,etc.).

Step 6 Repeatsteps4through5untilallcongurationsettingshavebeenadjustedtothedesired

values.

Step 7 Oncecongured,usethedownarrowtoleavetheCongurationMenu.

Inmostapplicationsonlyafew,ifany,congurationchangeswillbenecessary.Followingis

adescriptionofthecongurationsettingsandtheirfunctions:

C000 O-Peak Method of Charge Control -Setsthemethodofbrickcorechargingtobeused

duringo-peak(charge)periods.Heaterisconguredforautomaticchargecontrol,whichis

avalueofve(5).Toutilizemanualchargecontrol,changethevaluetosix(6).

C001 Start Brick Core Charge Set Point-IfutilizingautomaticchargecontrolassetinC000,this

value indicates the outdoor temperature at which the heater will start charging.

C002 Full Brick Core Charge Set Point -IfutilizingautomaticchargecontrolassetinC000,this

value indicates the outdoor temperature at which the heater will target a full core charge.

C003 Power Line Carrier (PLC) Channel Selection-IfusingPLCcommunication,thissettingmust

matchthechannelsettingintheSteesPLCtransmittingdevice.Avalueofzeroindicates

power line carrier communication is disabled.

C004 Optional Controls Conguration

Value Conguration Description

154 NoTimeClockModule/UtilizingPLCorManualChargeControl

155 NoTimeClockModule/DirectWiredOutdoorSensor

158 Time Clock Module/Manual Charge Control

159 Time Clock Module/Direct Wired Outdoor Sensor

C005 Control Switch Conguration-Ifutilizingpowerlinecarriercontrol,theSteestimeclock

moduleorlinevoltagecontrol,thisvalueshouldbezero.Forallotherapplications,thisvalue

should be one (1).

C006 ThiscongurationMUSTbesettoavalueofsix(6)forall2100Seriesroomheatingunits.

C007 Charge Factor-Thiscongurationshouldbesettoavalueofthirty(30).

C008-C012 Currently not utilized in 2100 Series room heating units.

C013-C021 Time Clock Module Conguration-Thesecongurationsettingsareusedtocongure

thepeakcontroltimeswhenutilizingtheoptionalSteesTimeClockModule.Refertothe

installationandcongurationinstructionsincludedwiththemoduleformoreinformation.

If access to Conguration

Menu times out, the system

must be powered o at the

circuit breaker and back on

to re-enter the menu.

IMPORTANT

2100 Series Installation 2.10

Installation 2.11 2100 Series

INSTALLER'S FINAL CHECK-OUT PROCEDURE

Withtheheaterde-energized,hingetherightsidepanel

open(PageA.08).Completethesystemcheck-outbelow:

Step 1 Inspectalleldconnectionstoensuretheyaretight

and that all wires are routed correctly.

Class II (low voltage) wiring or any wiring not

rated for line voltage should never be installed

in a line voltage area.

Step 2 Check the damper system to ensure the damper

operates freely and that there is no debris in this

area, which could inhibit its operation. To do so,

slowly press the damper lever extending from the

damperdownward.Becarefulnottobendthe

damperactuator.Ifthedamperisnotfree,remove

the blower and clean any debris from the damper.

Step 3 Make sure the blower operates by adjusting room

temperature set point above the actual room

temperature.

Step 4 Withthesysteminano-peak(charge)mode,

initiatethechargecontroloverride(Page1.03).

Step 5 Check for proper amperage draw on the charging

circuit(s).UsetheChargeCircuitAmperageDraw

Chartforreferencetothecorrectamperageofthespecicheaterbeinginstalled.

Step 6 Verify that the heater receives and responds to the utility peak control device and that all

other system controls are operating properly.

Step 7 Placegrillslatsinposition,ifremoved.

Grill slats should bow up to direct

airowup,awayfromtheoor.

Step 8 Placetherightsidepanelbackinto

position and secure.

Step 9 Returnthecontrolcircuitboardtoits

original position and install the painted

front panel.

Step 10Verifythatcongurationsettingsare

correctfortheapplication.Refertothe

CongurationMenu(Page2.10).

On start-up, odors and/or small

volumes of smoke relating to

rst time operation of the heating

components may occur.

Step 11 Make certain all fuses and/or circuit

breakers are labeled in the distribution

service panel as this system may be

connected to more than one branch

circuit.

Step 12Presentownerwiththemanualandwarrantyinformation.The owner's registration card

must be completed and returned to Stees Corporation to ensure warranty coverage.

The owner should retain the top portion of the card for their records.

WARNING

Risk of re. Can cause injury

or death. ETS devices run

for long periods of time at

high electrical loads. Poor or

marginal connections will cause

the connections to overheat and

fail.

Risk of electric shock. Can cause

injury or death. This heater may

be connected to more than

one branch circuit. Disconnect

power to all circuits before

installing or servicing. DO NOT

remove the painted front panel

while energized. Equipment

must be serviced by a qualied

technician.

CHARGE CIRCUIT AMPERAGE DRAW CHART

Input Wattage Woltage AMP Draw

1.32 kW 120 11.00

2.4 kW 240 10.00

3.0 kW 240 12.50

3.6 kW 240 15.00

4.5 kW 240 18.75

4.8 kW 240 20.00

5.4 kW 240 22.50

6.0 kW 240 25.00

7.2 kW 240 30.00

7.5 kW 240 31.25

9.0 kW 240 37.50

10.8 kW 240 45.00

(AMP draw is calculated by taking the total input wattage

divided by the input voltage. Allow +/- 5% tolerance at

nominal input voltage.)

Appendix

A

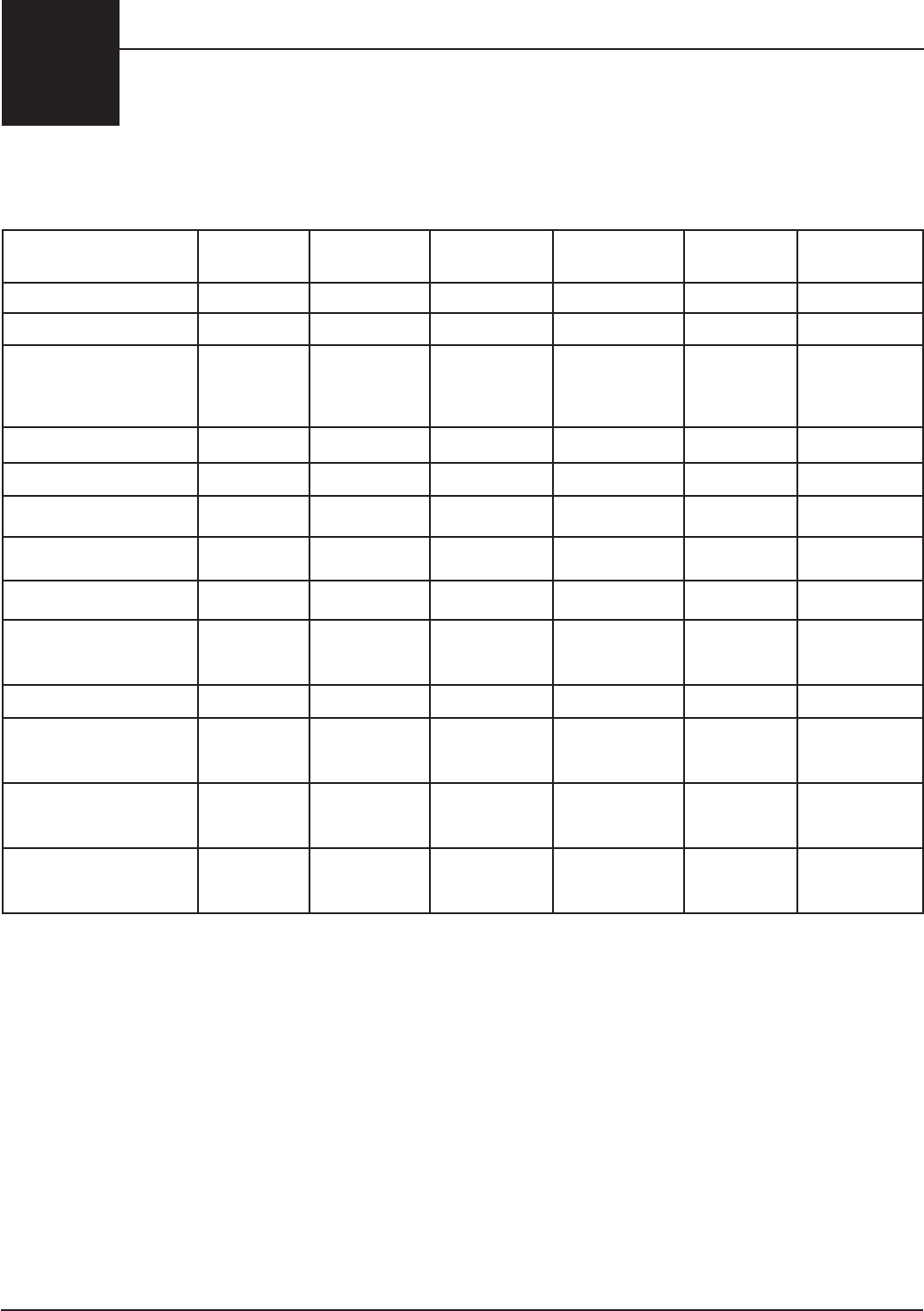

SPECIFICATIONS

* Refer to the Unit Identication Label on lower left side panel for data specic to your heater. In

standard conguration, the heater can be connected to 208V or 240V. Rated input at 208V is

75% of rated 240V input. If full rated input is required in 208V applications, contact the factory.

2100 Series Appendix A.01

Model 2102

plug-in

2102 2103 2104 2105 2106

Length-inches 30 30 37 44 51 58

Heights-inches 24.5 24.5 24.5 24.5 24.5 24.5

Depth-inches

(w/out wall bracket)

(w/wall bracket)

10.5

12

10.5

12

10.5

12

10.5

12

10.5

12

10.5

12

NumberofBricks 16 16 24 32 40 48

NumberofBrickPkgs. 8 8 12 16 20 24

WeightofHeater-lbs 105 91 112 126 145 164

WeightofBricks-lbs 176 176 264 352 440 528

InstalledWeight-lbs 281 267 376 478 585 692

*ElementVoltage 120

240 (std)

208&277opt

240 (std)

208&277opt

240 (std)

208&277opt

240 (std)

208&277

opt

240 (std)

208&277opt

*InputsAvailable-kW 1.32 2.4, 3.0, 3.6 3.6, 4.5, 5.4 4.8, 6.0, 7.2 6.0, 7.5, 9.0 7.2, 9.0, 10.8

*Blower/Control

Voltage

115 230 (std)

120 or 208

opt

230 (std)

120 or 208 opt

230 (std)

120 or 208 opt

230 (std)

120 or 208

opt

230 (std)

120 or 208 opt

BlowerWattage

Minimum

Maximum

30

120

30

120

30

120

30

120

30

120

30

120

Storage Capacity

kWh

BTU

13.5

46,062

13.5

46,062

20.25

69,093

27

92,124

33.75

115,155

40

136,480

Appendix A.02 2100 Series

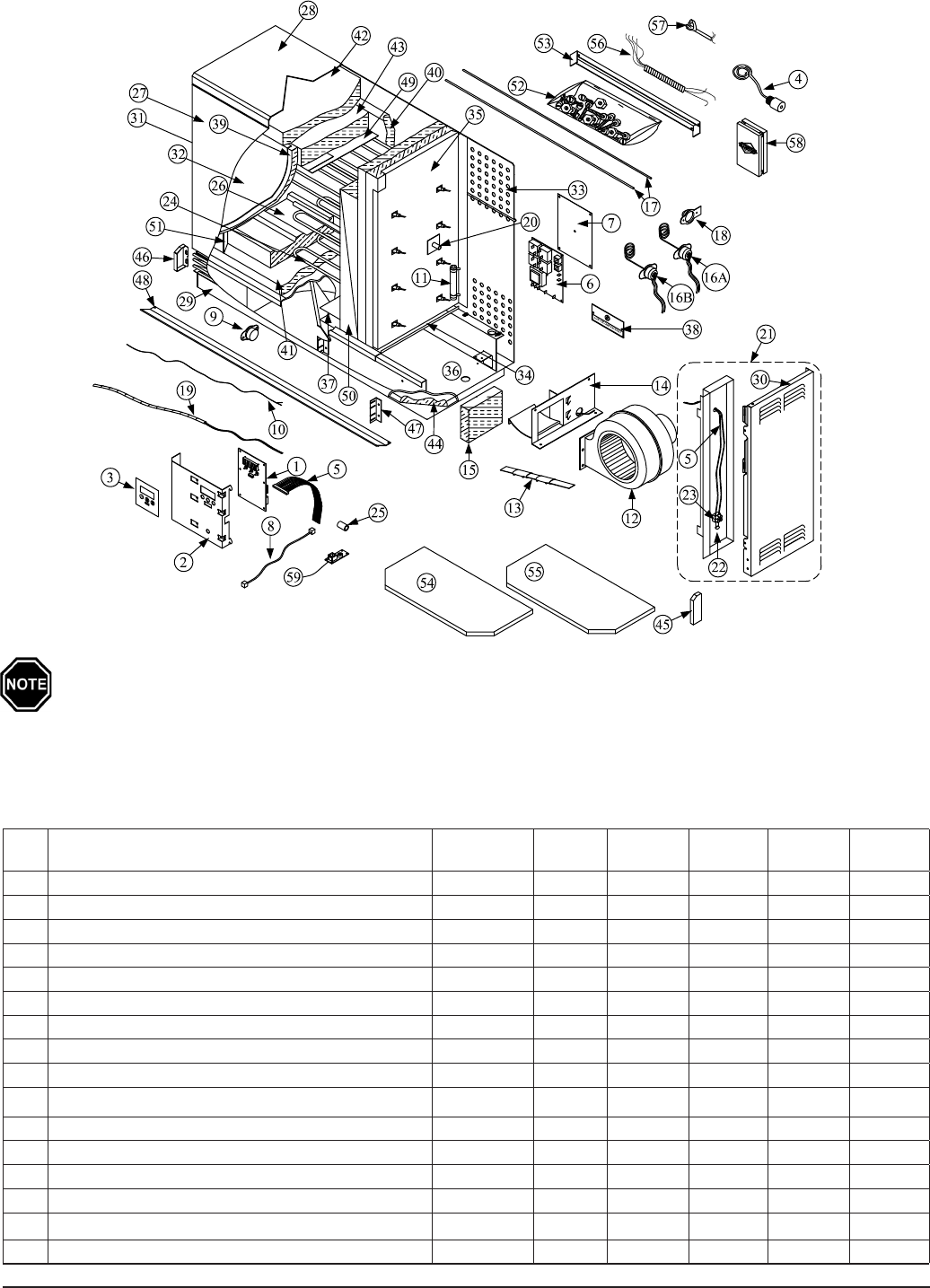

PARTS DIAGRAM

When ordering replacement parts, please include model number and serial number of the heater.

Ref

No.

Description

2102 Plug-in

Item #

2102

Item #

2103

Item #

2104

Item #

2105

Item #

2106

Item #

1. Processor Control Board 1023065R 1023065R 1023065R 1023065R 1023065R 1023065R

2. Processor Control Board Mounting Bracket 5943412 5943412 5943412 5943412 5943412 5943412

3. Faceplate Label 1159029 1159029 1159029 1159029 1159029 1159029

4. Outdoor Temperature Senor (optional) 1302033 1302033 1302033 1302033 1302033 1302033

5. Wiring Harness, Low Voltage 1011647 1011647 1011647 1011647 1011647 1011647

6. Base I/O Relay Board 1023078R 1023078R 1023078R 1023078R 1023078R 1023078R

7. Line Voltage Base I/O Barrier 1159060 1159060 1159060 1159060 1159060 1159060

8. Interface Cable, 18" 1010014R 1010014R 1010014R 1010014R 1010014R 1010014R

9. **Discharge Air High Limit Switch (285 Degree) Auto 1012018R 1012018R 1012018R 1012018R 1012018R 1012018R

" **Discharge Air High Limit Switch (285 Degree) Manual

1012080R 1012080R 1012080R 1012080R 1012080R 1012080R

10. Output Sensor (Thermocouple) 1040822 1040822 1040826 1040832 1040826 1040832

11. ***Blower Resistor (P-TECH) 1017047 1017049 1017049 1017049 1017049 1017049

" ***Blower Resistor (FASCO) 1017011 1017050 1017050 1017050 1017050 1017050

12. ***Blower Assembly (P-TECH) 1021036R 1021035R 1021035R 1021035R 1021035R 1021035R

***Blower Assembly (FASCO)

1021030R 1021032R 1021032R 1021032R 1021032R 1021032R

13. Damper Actuator Assembly 1043107R 1043106R 1043106R 1043106R 1043106R 1043106R

PARTS LIST

The blower resistor (Item #11) will vary depending on the blower (Item #12) installed in the heater.

Reference the Parts List for more details.

1.

2.

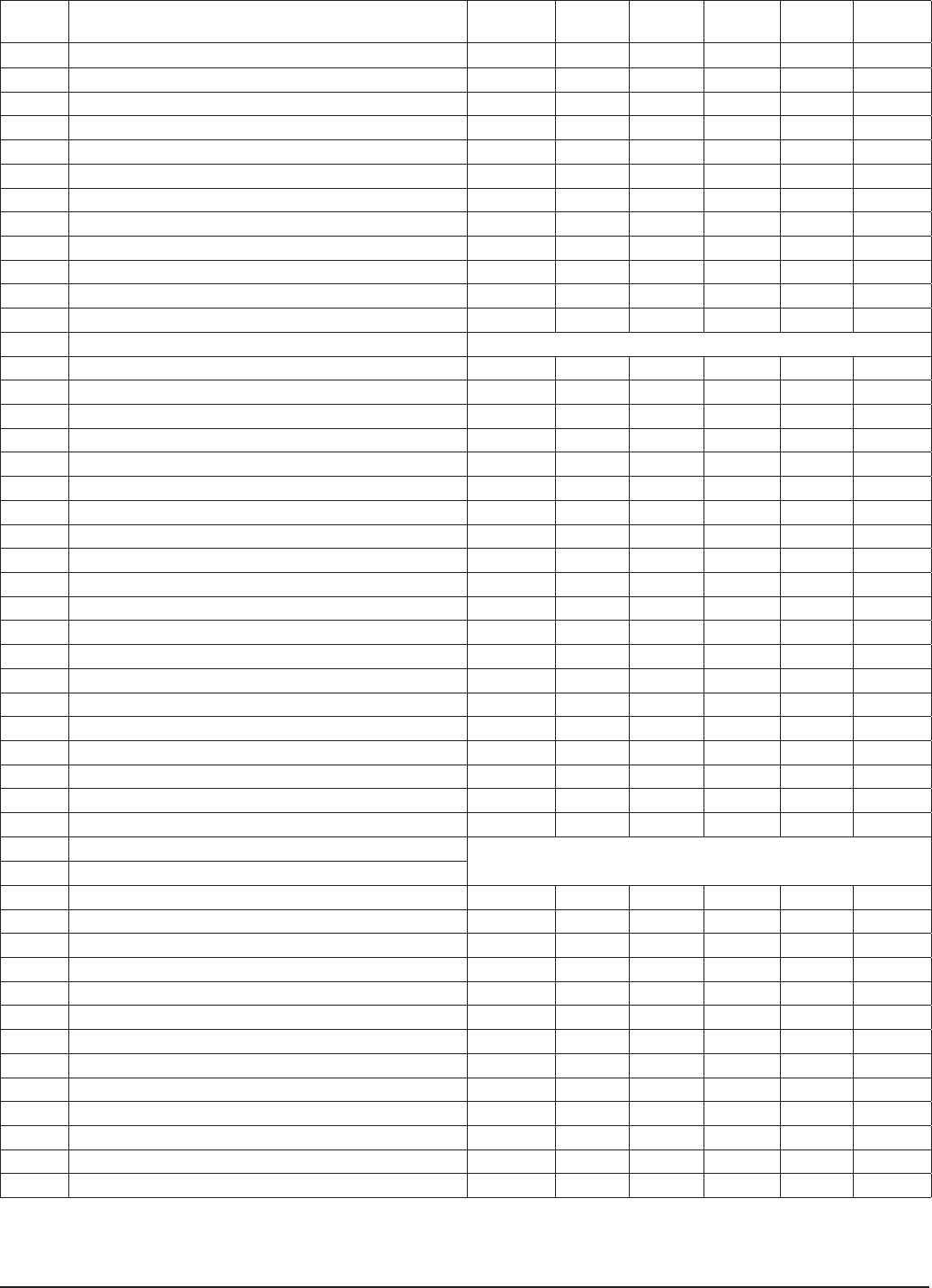

PARTS LIST CONTINUED

2100 Series Appendix A.03

*1012090R is a direct replacement in Model 2104.

**Manual and auto reset limits are not interchangeable. Verify serial number and/or style of limit switch before ordering.

***Optional voltages or wattages are available. Contact factory with model number and serial number of the heater.

Ref No. Description

2102 Plug-

in Item #

2102

Item #

2103

Item #

2104

Item #

2105

Item #

2106

Item #

14. Damper Assembly N/A N/A N/A N/A N/A N/A

15. Damper Assembly Insulation N/A N/A N/A N/A N/A N/A

16A. **Core Changing Limit Switch Auto (Back Panel) 1040816R 1040816R 1040816R 1040817R 1040817R 1040818R

16A. **Core Changing Limit Switch Manual (Back Panel) 1012088R 1012088R 1012088R 1012088R 1012090R 1012090R

16B. Clearance Violation Limit Switch Manual (Top Panel) 1012091R 1012091R 1012091R 1012091R 1012092R 1012092R

17. Core Changing High Limit Guide Tube (cut to size) 1105003 1105003 1105003 1105003 1105003 1105003

18. Core Changing High Limit Bracket 5940190 5940190 5940190 5940190 5940190 5940190

19. Brick Core Sensor (Thermocouple) 1043102R 1043102R 1043103R 1043103R 1043104R 1043104R

20. Brick Core Sensor Tube 5943222 5943222 5943220 5943220 5943220 5943220

21. Room Temperature Sensor Mounting Panel 1040860 1040860 1040860 1040860 1040860 1040860

22. Room Temperature Sensor 1013034 1013034 1013034 1013034 1013034 1013034

23. Terminal Block, Room Temperature Sensor 2- position 1016018 1016018 1016018 1016018 1016018 1016018

24. ***Heating Elements Contact factory with serial number of heater

25. High Temperature Vinyl 1015028 1015028 1015028 1015028 1015028 1015028

26. Heat Storage Brick 5903010 5903010 5903010 5903010 5903010 5903010

27. Painting Panel, Front 5943470 5943470 5943472 5943474 5943476 5943478

28. Painted Panel, Top (DO NOT REMOVE) 5943050 5943050 5943052 5943054 5943056 5943058

29. Painting Panel, Bottom 5943060 5943060 5943062 5943064 5943066 5943068

30. Painted Panel, Right 5943420 5943420 5943420 5943420 5943420 5943420

31. Painted Panel, Left 5943416 5943416 5943416 5943416 5943416 5943416

32. Galvanized Panel, Front 5943010 5943010 5943012 5943014 5943016 5943018

33. Galvanized Panel, Back 5943440 5943440 5943442 5943444 5943446 5943448

34. Galvanized Plate, Bottom 5943430 5943430 5943432 5943434 5943436 5943438

35. Galvanized Plate, Right 5943424 5943424 5943424 5943424 5943424 5943424

36. Galvanized Base Tray 5943450 5943450 5943452 5943454 5943456 5943458

37. Base Cap for Insulation 5943130 5943130 5943130 5943130 5943130 5943130

38. Low Voltage Raceway Cover 5943216 5943216 5943216 5943216 5943216 5943216

39. Insulation Panel, Front 1053010 1053010 1053012 1053014 1053016 1053018

40. Insulation Panel, Back 1053010 1053010 1053012 1053014 1053016 1053018

41. Insulation Panel, Bottom 1053020 1053020 1053022 1053024 1053026 1053028

42. 1 1/2" Blanket Insulation, Outer 1050005 1050005 1050005 1050005 1050005 1050005

43. 1 1/2" Blanket Insulation, Inner 1050004 1050004 1050004 1050004 1050004 1050004

44. 1" Blanket Insulation, Base 1050066 1050066 1050067 1050068 1050069 1050070

45. Grill End Bracket, Right

5943426 (includes one right and one left grill end bracket)

46. Grill End Bracket, Left

47 Grill Support Rail 5943024 5943024 5943024 5943024 5943024 5943024

48. Grill Slats 5943480 5943480 5943482 5943484 5943486 5943488

49. Aluminized Air Channel, Top Back 5949060 5949060 5949062 5949064 5949066 5949068

50. Aluminized Air Channel, Right 5943464 5943464 5943464 5943464 5943464 5943464

51. Aluminized Air Channel, Left 5949028 5949028 5949028 5949028 5949028 5949028

52. Mounting Hardware Package 1190038 1190032 1190032 1190032 1190032 1190032

53. Wall Support Bracket N/A 5943490 5943492 5943494 5943496 5943498

54. Security Base Shell 5942114 N/A N/A N/A N/A N/A

55. Security Base Filler 1190023 N/A N/A N/A N/A N/A

56. Wiring Harness (umbilical cord) Conduit N/A 1040800 1040800 1040800 1040800 1040800

57. Cord Assembly, Plug-in 1015000 N/A N/A N/A N/A N/A

58. Remote Room Temperature Senor (optional) 1302024 1302024 1302024 1302024 1302024 1302024

59. Time Clock Module (optional) 1301014 1301014 1301014 1301014 1301014 1301014

Appendix A.04 2100 Series

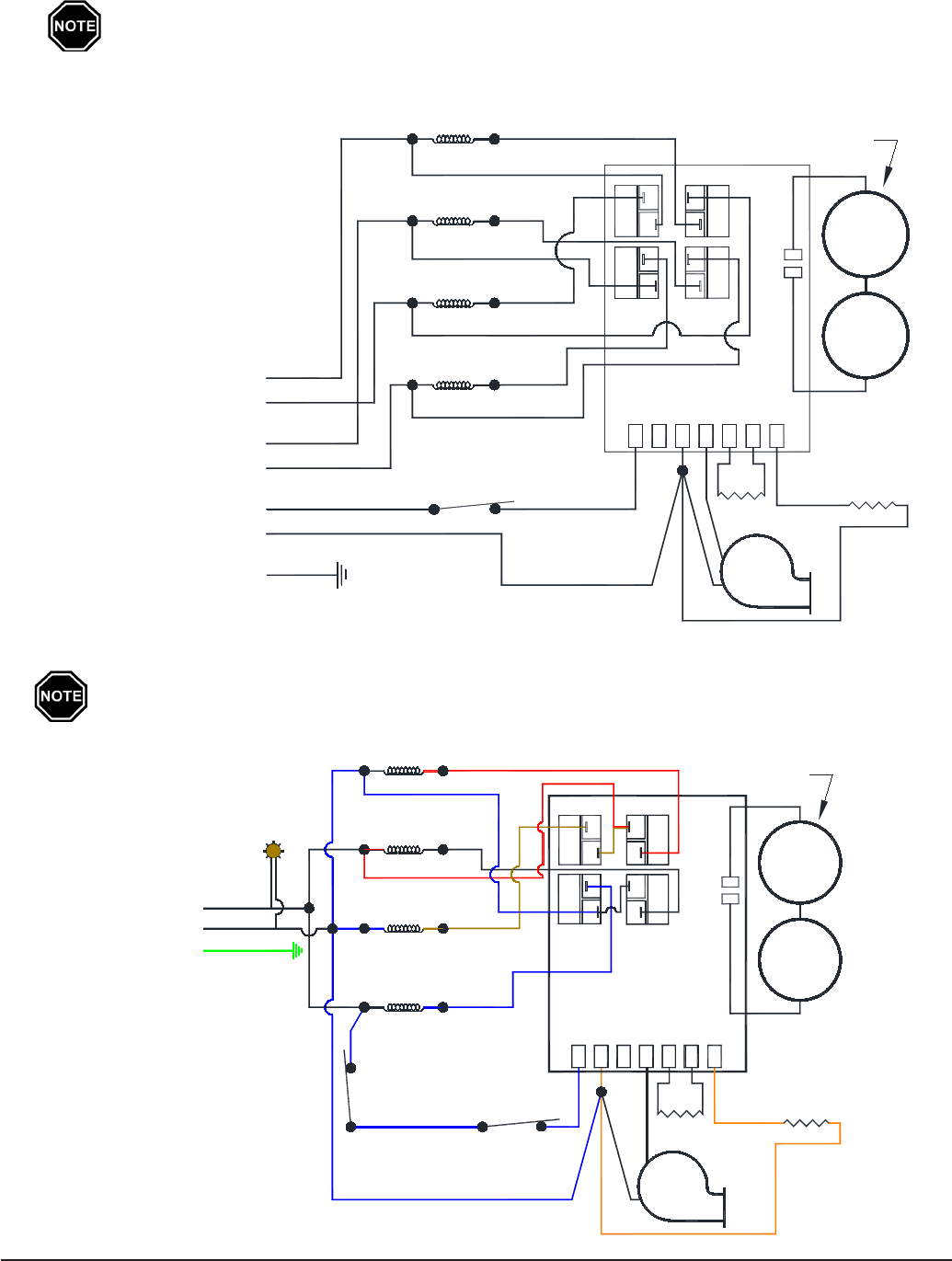

Models 2102, 2103, 2104 , 2105, and 2106

Connections shown are for systems with a 208/240V blower. If utilizing a 115V

blower and controls circuit, the blue/black (L1) connection must be the unground-

ed (hot) conductor of the power feed. Refer to the Unit Identication Label on the

lower left side panel for proper blower and heating element voltages.

Model 2102 (plug-in heater)

Connections shown are for systems with a 115V blower. Refer to the Unit Identica-

tion Label on the lower left side panel for proper blower and heating element volt-

ages.

INTERNAL LINE VOLTAGE WIRING DIAGRAMS

Black

Yellow

Blue

Blue

Blower Circuit

Green

Red

Black

Black

Blue/Black

Black

Charge Circuit #2

Heater Controls and

Limit

Temperature

Output

Red

Charge Circuit #1

Element #1

Element #2

Red

Element #3

Blue

Yellow

Element #4

Blower

Orange

Relay #1

Relay #3

Limit

Base I/O PCB

Resistor

L1

Resistor120 240 Blower

Control

Resistor

Orange

Damper

Damper

Relay #4

Relay #2

Charging

Clearance

Violation

Limit

Red

If Equipped from Factory

SWITCH

Element #1

Element #2

Element #3

Element #4

Blue/Black

Blue

Power

Cord

Black

TIP

Green

White

Blower

Orange

Relay #1

Relay #3

Base I/O PCB

Resistor

Resistor

Output

Temperature

Limit

120

L1

Blower240

Damper

Control

Resistor

Orange

Damper

Blue

Yellow

Charging

Limit

If Equipped from Factory

Black

Relay #2

Relay #4

Clearance

Violation

Limit

Red

Power

Indicator

Light

MANUAL RESET LIMIT CONTROLS

2100 Series Appendix A.05

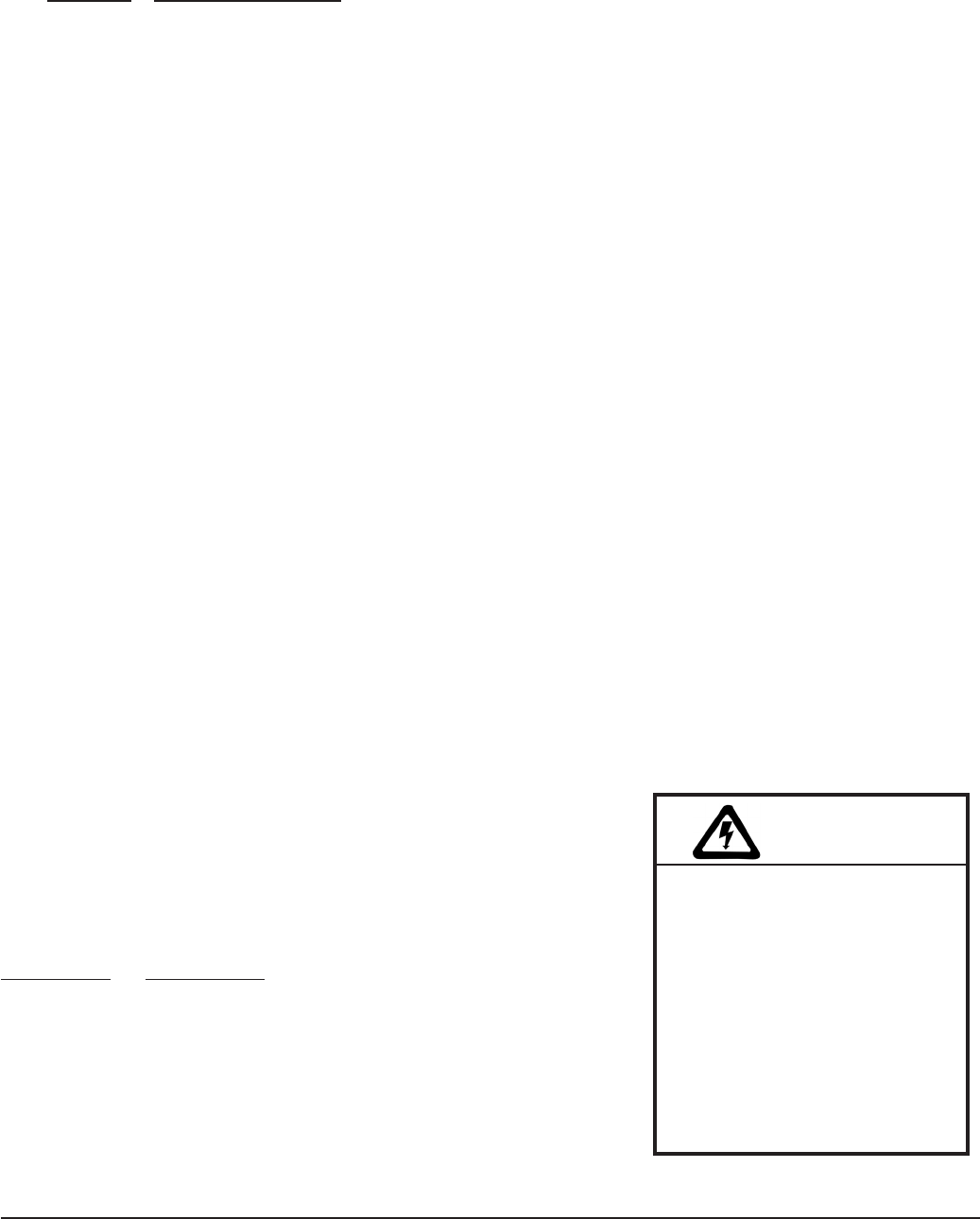

INTERNAL LOW VOLTAGE WIRING DIAGRAM

Clearance Violation Limit:Locatedinsidetheheaterintheupperfront

corneroftheelectricalcompartment.Activationofthiscontrolwouldbe

indicatedbythedisplayscrolling“core”“fail”andwouldindicatethattheheater

has malfunctioned. Contact service technician to troubleshoot and repair the

root cause of the condition.

Discharge Air High Limit: The discharge air high limit is located in the lower

leftportionofthegrillareaandcanbeaccessedthroughthegrill.Activationof

this control would be indicated by a blank display screen. This control can be reset

by pressing the button on the limit control located just inside of the discharge air

grills.Ifthiscontrolactivatesmultipletimes,contactaqualiedservicetechnician

for repairs.

The discharge air high limit, the core charging high limit, and the clearance

violation limit switches are all manual reset limit controls installed for safety

purposes.Ifoneoftheselimitcontrolsopens,itmustbemanuallyresetbefore

operating the heater. To reset the limit controls, press and release the reset

button located in the middle of the control.

Risk of electric shock. Do not disassemble the

heater. There are no user serviceable parts inside.

WARNING

Gray

Gray

Purple

Purple

Blue

Yellow

Blue/White

M

Black

Green

Red

Red

Yellow

Yellow

-

+

+

-

A

P

M

M

Outdoor Sensor

Built-in or Remote Mount

Automatic Charge Control

Room Sensor

Outdoor Sensor

Room Sensor

Anticipated Peak Control (Specialty Applications)

Low Voltage Common (Grounded)

Room Temperature Set Back

Brick Core Sensor (Thermocouple)

Output Sensor (Thermocouple)

Peak Control

Low Voltage Hot

Core Charging High Limit: Locatedinsidetheheateratthebackof

theelectricalcompartment.Activationofthiscontrolwouldbeindicated

bythedisplayscrolling“core”“fail”andwouldindicatethattheheaterhas

malfunctioned.Iftheheaterisequippedwitha1/8”limitresetholeintherear,

upperlocationintheheater’ssidepanel,thislimitcanbereset.Iftheheateris

not equipped with this remote reset feature or if there has been multiple trip

conditions, contact service technician to troubleshoot and repair the root cause

of the condition.

Appendix A.06 2100 Series

HELP MENU

The 2100 series room heating unit contains a Help Menu which may be accessed by pressing and

releasing the Mbuttonuntil"HELP"isdisplayedonthefaceplate.Scrollthroughthemenuby

pressing either the up or the down arrow button.

Display

Reading Description

Fxxx FirmwareVersionNumber-Indicatestheversionofsoftwareinstalled.

Oxx OutdoorTemperature-Indicatescurrentoutdoortemperatureasrecognizedbythe

heater.

tL:xx TargetLevel-Indicatesthepercentageofbrickcorechargetheheatertargetsduring

ano-peakperiod.

CL:xx ChargeLevel-Indicatesthepercentageofheatstoragecurrentlyinthebrickcore.

HEx HeatingElementsActive-Indicatesthenumberofheatingelementscurrently

energized.

PCx PowerLineCarrierChannel-Indicatesthechannelonwhichtheheaterissetto

receivePLCcommunicationsignal.

Px PowerLineCarrierNetHitRatePercentage-Indicatesthepercentageof"GOOD"

communicationpacketsreceivedbytheheaterfromthePLCtransmittersystem.

PSx IndicateswhichSpecialtyTimerthesystemiscurrentlyusing.Thevaluedisplayed

will be zero if the Specialty Timer is not being utilized.

CC_x ChargeModeOperation-Indicatesthechargecontrolmethodbeingutilizedduring

o-peakperiods.

CA_x A-PeakModeOperation-Indicatesthechargecontrolmethodbeingutilizedduring

anticipated peak periods.

C1_x SpecialtyTimer#1ChargeMode-SpecialtyApplicationsOnly.

C2_x SpecialtyTimer#2ChargeMode-SpecialtyApplicationsOnly.

HUxx HeatUsage-Indicatestheamountofinputbeingdissipatedbythesystem.

A_xx TargetDischargeAirTemperature-Indicatesthedischargeairtemperaturethatthe

system is targeting.

cxxx CompressorOutputRelayDelayTimer-Indicatestimeremainingbeforeheatpump

compressorisenergized."cON"indicatestheheatpumpisenergized.

ERROR CODES

2100Seriesheatershaveanon-boarddiagnosticsystemtomonitorvariousoperatingconditions.If

operating conditions move outside the normal operating range,

anerrorcodewillbedisplayedonthefaceplate.Ifthereare

multiple errors simultaneously, only the highest priority error

code will be displayed. Once corrected, the next highest priority

codewillbedisplayed.Errorcodeswillbedisplayedonthe

faceplateas“Er—”(i.e.Er05).

Error Code Description

01 Core temperature sensor reading is out of normal

range.Anopen,shorted,orotherwisedefective

sensor or a circuit board which is out of calibration

could cause this.

02 Contactaqualiedservicetechnician.

HAZARDOUS VOLTAGE:

Risk of electric shock. Can

cause injury or death. Heater

may be connected to more

than one branch circuit.

Disconnect power to all

circuits before servicing.

DO NOT remove the painted

front panel while energized.

Equipment must be serviced

by a qualied technician.

WARNING

Error Code Description

03 Roomthermistortemperatureisoutofnormalrange.Thismayindicateanopen

thermistor, a short in the wiring, or a circuit board which is out of calibration.

04 Dischargeairtemperatureisoutofnormalrange.Ensureproperoperationofthe

dampersystem.Also,anopen,shorted,orotherwisedefectiveoutputsensorora

circuit board which is out of calibration could cause this.

05 Outdoor sensor (direct wired) temperature reading is out of normal range. The

thermistor circuit may be open or shorted, the processor control board may be out of

calibration,ortheremaybeanincorrectvalueinL035.

06 Outdoorsensortemperaturefromthetransmittingdevice(PLCsystem)isoutof

normal range. Check the outdoor sensor attached to the transmitting device and the

transmitter for proper operation.

07 Processorcontrolboardtemperaturesensorisoutofnormaloperatingrange.Verify

that none of the clearances have been violated and inspect the condition of the

processor control board.

08 Currently not utilized.

09 Currently not utilized.

10 Discharge air temperature has exceeded maximum operating temperature.

20 ThereisnocommunicationoccurringbetweentheBaseI/Oboardandtheprocessor

control board. This may be caused by a defective board interface cable or an

unresponsiveBaseI/Oboard.

21 Contactaqualiedservicetechnician.

22 Contactaqualiedservicetechnician.

23 ThereisnocommunicationoccurringwiththeSteesTimeClockModule.

24 Temperaturesensoroset/referenceisoutofrangeandindicatesthatoneofthe

sensors may be shorted to ground or the processor control board may be out of

calibration.

25 Contactaqualiedservicetechnician.

26 InsucientMainControlBoardMemory.Contactaqualiedservicetechnician.

27 InsucientPermanentMemory.Contactaqualiedservicetechnician.

28 Permanentmemorychangehasbeenmade.PresstheM buttontoaccept.Asthis

error message indicates a change has been made to the software program, it is

important to verify that all location settings are correct for the application.

29 On-boardcommunicationsystemisnotfullyoperable.Contactaqualiedservice

technician.

30 BaseI/Ocircuitboardisintestmode.Checkthejumpercongurationonthecircuit

board.

31 Contactaqualiedservicetechnician.

39 IndicatesthevalueinConguration2(C002)hasbeensettoavaluegreaterthanthe

valueinConguration1(C001).ThesystemwillnotchargeuntilthevalueinC002is

set lower than C001.

40 PressandreleasetheMbuttontocleartheerror.Iftheerrorcodereappears,contact

aqualiedservicetechnician.

41-44 Contactaqualiedservicetechnician.

Cold Core The temperature of the brick core has dropped below 40 degrees or the brick core

sensor may be open. Verify that the brick core sensor wiring is connected properly.

CoreFail Corechargingand/orclearanceviolationhighlimitswitchmaybeopen.

PLCFail Thesystemisconguredforpowerlinecarrier;however,isnotreceivingavalid

power line carrier communication signal.

2100 Series Appendix A.07

Appendix A.08 2100 Series

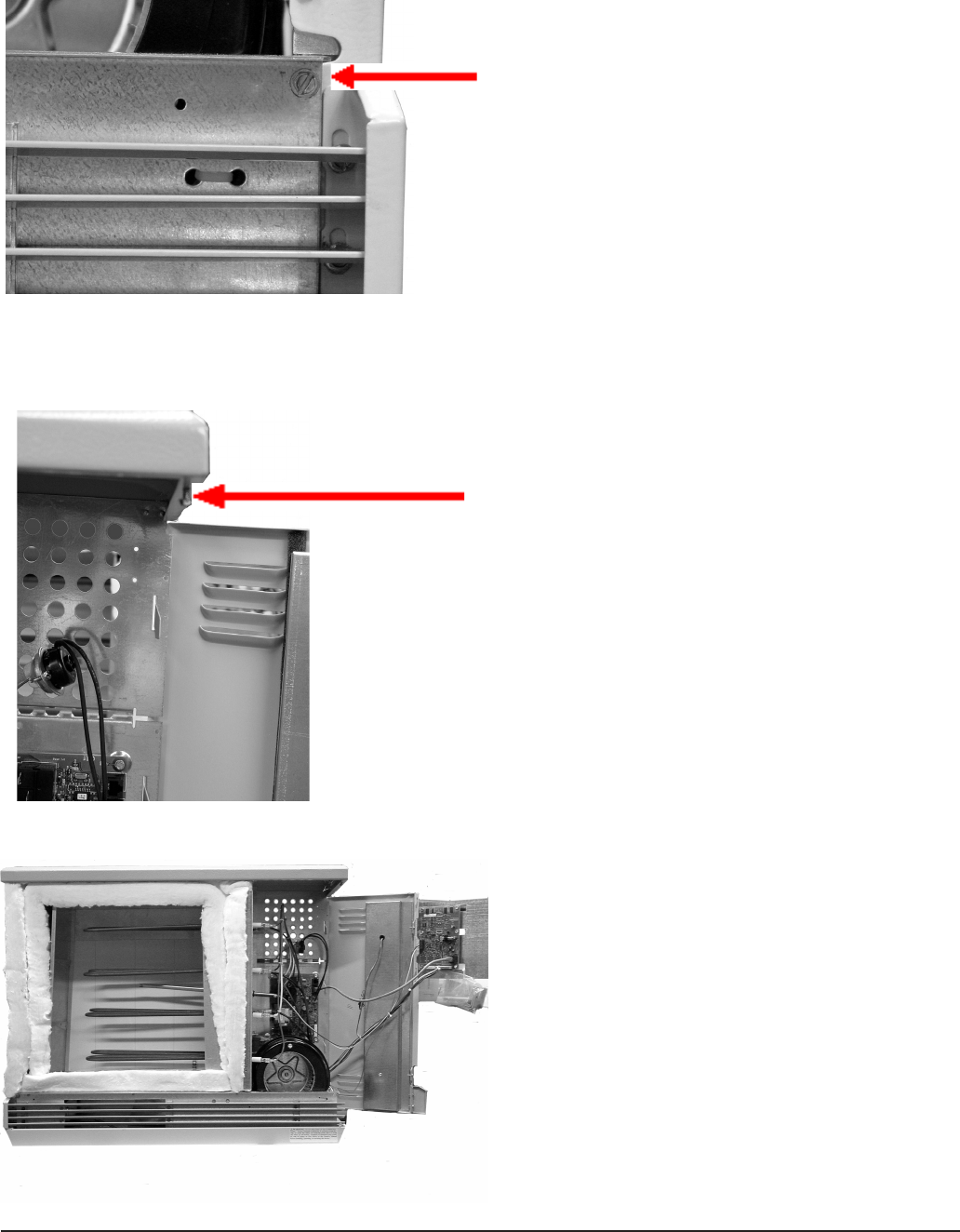

HINGING THE RIGHT SIDE PANEL

Foreaseinservicing,therightsidepanelofthe2100Seriesroomheatingunithingesopen.Fol-

low the instructions below to hinge the right side panel:

1. Withthepaintedfrontpanelo,remove

the screw located above the grill slats on

the lower right side of the heater.

2. Loosenthescrewlocatedatthetopright

corner of the electrical compartment.

3. Pushoutontherightsidepanel.

Anticipated Peak ~ Usedonlybycertain

power companies as an alternative method

ofstoringheatinthebrickcore.Indicatedby

an"A"onthesystemdisplay.Alsoreferred

toas"Pre-Peak".

Automatic Charge Control ~ Method

of brick core charge regulation where a

sensor monitors outdoor temperature

to automatically adjust the brick core

temperature.

Brick Core Charge Level ~ The amount of

heat currently stored in the brick core of the

heater.

Charge Period ~ O-peaktimeinwhich

the system is allowed to store heat in its

brickcore.Indicatedbya"C"onthesystem

display.

Control Panel~ Contains the buttons to

adjust and the display to indicate heater

functions.Locatedonthefrontoftheheater

in the upper right corner.

Control Period ~ On-peaktimeinwhich

the system is not allowed to store heat in its

brickcore.Indicatedbya"P"onthesystem

display.

Edit Mode ~ Processofchangingorviewing

the values in a microprocessor location.

This is accomplished with the use of the M

(mode) button, the (up arrow) button, and

the (down arrow) button.

Location (Function) ~ Wherethespecic

operating information of the heater is

stored. These locations are part of the

heater's microprocessor and are accessed

through the heater's control panel.

Displayedasan"L"onthefaceplatewhenin

the edit mode.

Location Value ~ Thespecicinformation

set and stored in a location on the heater's

microprocessorwhichdenesheater

operation.Avalueforaspeciclocationis

accessed through the heater's control panel.

Manual Charge Control ~ Method of

brick core charge regulation where the

owner must periodically adjust the brick

core temperature setting in relation to the

outdoor temperature.

Microprocessor ~ Device on the circuit

board of the heater which stores and

processes the information for controlling the

operation of the heater.

O-peak ~ The time during the day or

night when the power company can supply

electricity more economically and may

oeraspecialincentivesuchasareduced

electric rate or billing credits for the electricity

consumed during this time. Typically, electrical

usageisnotcontrolledduringano-peak

time. (The heater will provide heat to satisfy

comfort requirements during this time as well

as charge or store heat in its brick core.)

On-peak ~ The time during the day or night

when the power company experiences

a high demand for electricity. To limit

demand, certain appliances are controlled

to avoid usage by them and/or a premium

for the electricity consumed during this time

may be charged to discourage electrical

usage. (The heater is not allowed to charge

or store heat in its brick core during peak

periods.Heatingrequirementsaresatised

by the heat stored in its brick core during the

previouso-peakperiod.)

Outdoor Sensor ~ Device that senses

outdoor air temperature and communicates

this information to the heater.

Pre-Peak ~ Usedonlybycertainpower

companies as an alternative method of

storingheatinheater'sbrickcore.Also

referredtoas"AnticipatedPeak".

Room Temperature Set Point ~ The desired

room temperature the heater is to maintain

assetbytheowner.Iftheroomthermostat

senses a temperature below this point, the

heater's blower will come on and extract

heat from the brick core.

GLOSSARY

2100 Series Appendix A.09

DOCUMENT #1200340 REV 21

Registeringyourpurchaseisanessentialsteptoensurewarrantycoverage.AWarrantyRegistration

card is included with the Owner's Manual. Simply complete, detach the bottom portion, and return

thecardtoday.Retainthetopportionofthecardforyourles.

Warranty

Thank you for purchasing Steffes ETS heating equipment. We welcome your comments

relating to the heater and this manual. Enjoy your new purchase!

3050Hwy22North•Dickinson,ND58601-9413•www.stees.com

W

WARRANTY STATEMENT

Steeswarrantsforaperiodofve(5)yearsfollowingdelivery,limitedtoseven(7)yearsfromdate

ofmanufacture,ofanygoodsprovidedunderthisAgreementthatthegoodspurchasedhereunder

will be of merchantable quality, free from defects in material and workmanship, and that the goods

providedwillbenewandconformtothemechanicalandperformancespecicationsreferencedinany

drawingsprovidedbyStees.CustomershallpromptlyprovidenoticetoSteesofanygoodswhich

do not comply with such warranty.

THEWARRANTIES SET FORTHHEREIN ARE STEFFES’SOLE AND EXCLUSIVEWARRANTIES, AND THEY

AREMADEINLIEUOFALLOTHERWARRANTIES.THEREARENOOTHERWARRANTIES,EXPRESSOR

IMPLIED,WHETHERARISINGBYOPERATIONOFLAW,STATUTE,USAGEOFTRADE,CUSTOM,COURSE

OF DEALING OR PERFORMANCE, THE PARTIES’ CONDUCT OR OTHERWISE, FOR ANY PRODUCTS,

SERVICESOROTHERITEMSSOLDORFURNISHEDBYSTEFFES.WITHOUTLIMITINGTHEGENERALITY

OFTHE FOREGOING,ANDEXCEPTTOTHEEXTENTEXPRESSLY STATEDHEREIN,STEFFESDISCLAIMS

ALL IMPLIED WARRANTIESOF MERCHANTABILITYAND FITNESS FOR APARTICULAR PURPOSEAND,