GARD

TM

skin Assay Protocol

Genomic Allergen Rapid Detection (GARD) assay for assessment of skin

sensitizers (GARDskin) assay protocol

The Genomic Allergen Rapid Detection skin (GARDskin) is an in vitro assay that provides

binary hazard identification of skin sensitizers (i.e. UN GHS Category 1) versus non-

sensitizers). The method evaluates the transcriptional patterns of a specific genomic

biomarker signature, the GARDskin prediction signature (GPS), in the SenzaCell cell line

exposed to test chemicals.

Résumé

The purpose of the test method is to contribute to the identification of skin sensitisers and

non-sensitisers by providing information on the chemical-induced alteration of gene expression

of mechanistically relevant genomic biomarkers associated with the activation of dendritic cells

(DC). The activation process through which DC change from antigen processing to antigen

presenting cells addresses the third key event of the skin sensitisation Adverse Outcome

Pathway (AOP).

Experimental Description

Endpoint Measurement

After test chemical exposure of SenzaCell cells, the expression of the GPS, comprising 196

gene transcripts, is quantified utilizing the nanoString technology.

Endpoint Value(s)

The gene expression of the GPS is analysed with a fixed SVM algorithm that generates

“Decision Values” (DVs). From triplicate replicate experiments the mean DV is calculated. If

the mean DV is ≥0 the test chemical is classified as a skin sensitizer. If the mean DV is <0 the

test chemical is classified as a non-sensitizer.

Experimental System

The biological Test System is a human myeloid dendritic like cell line, SenzaCell, which is a

subclone from the MUTZ-3 cell line. SenzaCells are deposited at ATCC and can be purchased

from SenzaGen AB.

GARDskin Page 2 of 41

Discussion

GARDskin assay overview

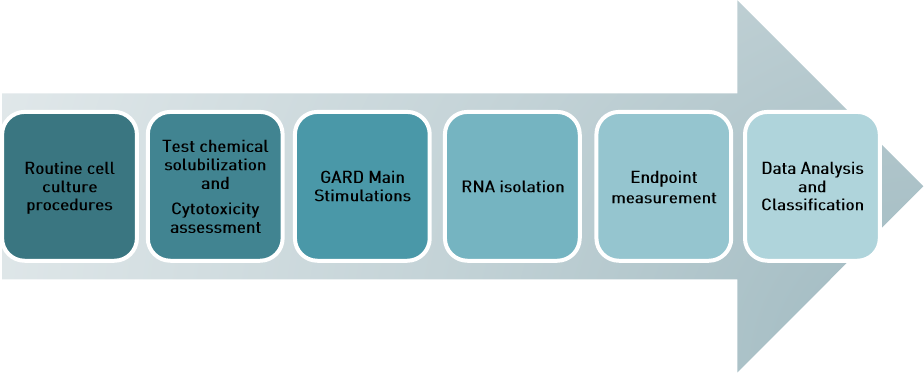

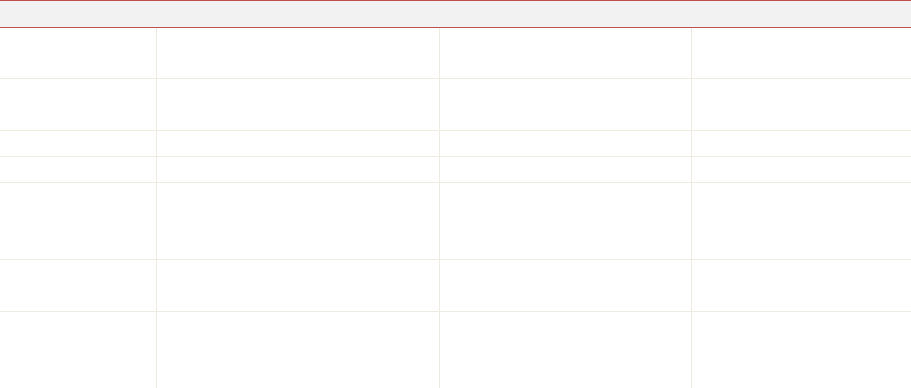

Figure 1 GARDskin assay workflow. First the SenzaCells are cultured according to standard procedures. Then the Test Item is

solubilized and the Test Item cytotoxicity is assessed . Main stimulations follow to generate RNA samples which are the basis

for the endpoint measurement, data analysis and classification.

Figure 1 describes the workflow of the GARDskin assay, starting with routine cell culturing of

SenzaCell cell line. In the GARDskin assay, cell stimulations with a test chemical are

performed for two reasons: 1) cytotoxicity assessment to identify a relevant stimulation

concentration, and 2) for the GARDskin Main Stimulation to harvest RNA.

In the cytotoxicity assessment, the test chemical is screened for cytotoxic effects, to identify an

appropriate concentration (i.e. the concentration that yields a Relative viability of ~90%, Rv90)

to be used as the input concentration in the GARDskin Main Stimulations. The cells are

exposed to a range of concentrations of the test chemical, originating from a serial dilution.

Once the input concentration of the test chemical is found, cells are exposed to the test

chemical again in the GARDskin Main Stimulations with the concentration identified during the

cytotoxicity assessment. Main stimulations are repeated three times to achieve three biological

replicate samples. Thus, every GARDskin assessment of a test chemical is based on three

replicate GARDskin Main Stimulations.

The endpoint measurements of GARDskin, i.e. the quantification of the GARDskin biomarker

signature mRNA transcripts, is performed on total RNA purified from cells from the GARDskin

Main Stimulation. The quantification is performed using the NanoString nCounter instrument

and endpoint specific biomarker CodeSets. The result is analyzed with the GARD Data

Analysis Application (GDAA) and the test chemical is classified as a sensitizer or non-

sensitizer.

GARDskin Page 3 of 41

Status

Development

Lund University (Sweden)

SenzaGen AB (Sweden)

Known Laboratory Use

EuroFins GB

BRT

MB Research laboratory

SenzaGen AB

Participation in Validation Studies

SenzaGen has organized and completed an inter-laboratory validation study in which the

method was transferred to 2 laboratories (see below) and the predictive capacity was also

evaluated in each laboratory (Johansson et al.

Toxicological Sciences, 2019).

Burleson Research Technologies Inc, 120 First Flight Lane, Morrisville, NC, USA.a.

Eurofins BioPharma Product Testing Munich GmbH, 82152 Planegg/Munich Germany

An independent peer review by the EURL ECVAM Scientific Advisory Committee (ESAC)

regarding the SenzaGen-coordinated Performance Standards-based validation of the

GARDskin method for skin sensitisation testing has been published in July 2021 (ESAC,

2021).

Regulatory Acceptance

The test method is under review by the OECD (2021).

Proprietary and/or Confidentiality Issues

Intellectual property rights

The SenzaCell cell line is available under a license agreement upon request. The IP rights of

the GARD biomarker signatures and any assay utilizing the signatures, in its entirety or parts

thereof, are owned by SenzaGen AB.

This Document, its contents and any other intellectual property rights referred to in this

document, are the property of SenzaGen AB and are intended solely for guidance concerning

performing the GARDskin assay and shall belong to and vest in SenzaGen AB absolutely to

the fullest extent permitted by law.

Any patent, registered trademarks, copyright and/or other intellectual property right of

SenzaGen AB shall belong to and vest in SenzaGen AB absolutely to the fullest extent

permitted by the applicable laws. To SenzaGen knowledge, none of the offered products sold,

nor any process or know-how used, by SenzaGen infringes or is alleged to infringe any patent

or other intellectual property rights of any other Person.

GARDskin Page 4 of 41

This document and translations of it may be copied and furnished to others, and derivative

works that comment on or otherwise explain it or assist in its implementation may be prepared,

copied, published and distributed, in whole or in part, without restriction of any kind, provided

that the copyright notice “©2019 SenzaGen AB. All rights reserved “ and this paragraph are

included on all such copies and derivative works. However, this document itself may not be

modified in any way, such as by removing the copyright notice.

Disclaimer

To the maximum extent permitted by law, SenzaGen (on behalf of itself and SenzaGen

affiliates, licensors, distributors, agents, consultants, supplier, subcontractors and employees)

expressly disclaim all representations and warranties concerning the scope or validity of the

intellectual property rights, and expressly disclaim any warranty that the contents of any

documents or the developed products referred to herein in connection with any add on content

or the use of the intellectual property rights by licensee will not infringe upon patent, copyright,

trademark or other proprietary rights of a third party. Any warranty that may be provided in any

applicable laws, statute or regulation governing commercial activities is explicitly disclaimed.

Health and Safety Issues

The human myeloid leukemia cell line (SenzaCell) is a cell line of Biosafety level I. As such, no

extraordinary safety issues are considered necessary, beyond those considered common for

sterile work with mammalian cell lines in laboratories dedicated for such purposes.

The testing laboratory should have in place routines for risk assessment of chemicals. This

routine should take into account the information in the SDS and state safe ways of working

and waste handling of chemical substanses.

The positive control, proficiency chemicals, and vehicles used in the GARDskin assay need to

be handled according to available information, such as SDS, since these can be e.g.

sensitizing, acutely toxic, and environmentally hazardous etc. The safe handling of a test

chemical in the GARDskin assay need to be assessed on a case to case basis. In the case of

an unknown test chemical it is recommended to consider it as a sensitizer and a highly toxic

compound and use appropriate protection.

The TRIzol or equivalent reagents are corrosive and carcinogenic and should be handled

according to instructions provided by the supplier and according to available safety data sheet

(SDS).

Propidium iodide is suspected to cause genetically defects and is a known irritant compound

which should be used with care according to SDS.

General precautions

Always wear protective clothing and gloves and work in a fume hood when handling chemical

substances and the TRIzol reagent. Wear protective glasses and breathing mask when

handling the original stocks (powder or liquid) of the chemical substances, and preferably also

disposable arm cuffs to avoid contact with the chemical substances.

MSDS Information

Positive control and solvents (negative controls), see CAS number and Catalog number in

Table 3, read available MSDS.

GARDskin Page 5 of 41

Abbreviations and Definitions

Annotation file A text file used by the digital analyzer during the endpoint analysis to

map individual RCC files to substance names and gene signatures.

BSA Bovine Serum Albumin (used to prepare flow cytometry buffer)

CDF Cartridge Definition File (defines sample specific data to associate with

the data output and defines the parameters for the imaging instrument

to use during image collection and processing)

Cell batch Within the context of this protocol, a unique cell batch is defined as:

- cells originating from different frozen vials, or…

- cells originating from the same frozen vial, which have been

cultivated separately. A division of cell cultures for the purpose of

achieving separate cell batches should be done no sooner than

passage 3 after thawing, and no later than at least 2 passages prior to

exposure experiments.

DMF Dimethylformamide (may be used to solubilize test chemicals)

DMSO Dimethyl Sulfoxide (may be used to solubilize test chemicals)

D-PBS Dulbecco’s Phosphate Buffered Saline (used to prepare flow cytometry

wash buffer)

DV Decision Value (the assay readout)

FBS Fetal Bovine Serum (a supplement to the cell culture medium)

FITC Fluorescein isothiocyanate (a derivate of fluorescein which can be

conjugated to antibodies. Its fluorescence is detected by flow cytometry

analysis)

FSC-A The Forward Scatter (Area) of the particle population is a parameter that

can be detected by a flow cytometry. A higher value corresponds to

larger particles.

GARD Genomic Allergen Rapid Detection

GDAA GARD Data Analysis Application (a web interferace used to analyse the

GARDskin end-point)

GHS Globally Harmonized System

GM-CSF Granulocyte Macrophage Colony Stimulating Factor (a growth factor

supplemented to the cell culture medium)

GPS GARD Prediction Signature (the transcripts measured in the GARDskin

assay)

GARDskin Page 6 of 41

In-well concentration The test and/or control chemical concentration in the exposed

SenzaCell cell culture during a stimulation

mAbs Monoclonal antibodies (used for the phenotype control)

Main Stimulation Cell stimulation performed to generate RNA. Each GARDskin test

consists of three Main Stimulations

PI Propidium Iodide (PI is a fluorescent substance that intercalates in DNA.

Since viable cells have an intact cell membrane, those will not be

stained. The fluorescent signal can be detected by flow cytometry and is

used to assess cell viability)

PE Phycoerythrin (a fluorochrome that can be conjugated to antibodies. Its

fluorescence can be detected by flow cytometry analysis).

PPD p-Phenylenediamine (the GARDskin positive control chemical)

RCC Reporter Code Count (the file type that is generated by the nCounter

System)

RLF Reporter Library File (a file that contains the code key information used

during image processing in the digital analyzer to assign target identities

to the barcode)

Rv90 90% relative viability (the concentration of a test chemical or positive

control chemical inducing 90 % relative viability. Calculated after flow

cytometry analysis of PI stained cell cultures)

SVM Support Vector Machine

SSC-A The Side Scatter (Area) of the particle population is a parameter that

can be detected by flow cytometry. A higher value corresponds to more

granular particles.

TC flask Tissue Culture flask

PROCEDURE DETAILS

Materials and Preparations

Cell or Experimental system

The human myeloid leukemia cell line SenzaCell is provided by SenzaGen AB and sent to the

licensed CRO on dry ice. The provided vial should be stored in liquid nitrogen or a cryogenic

freezer. The vial should be expanded and frozen in liquid nitrogen or a cryogenic freezer as a

homogenous cell bank according to instructions from the developing laboratory.

GARDskin Page 7 of 41

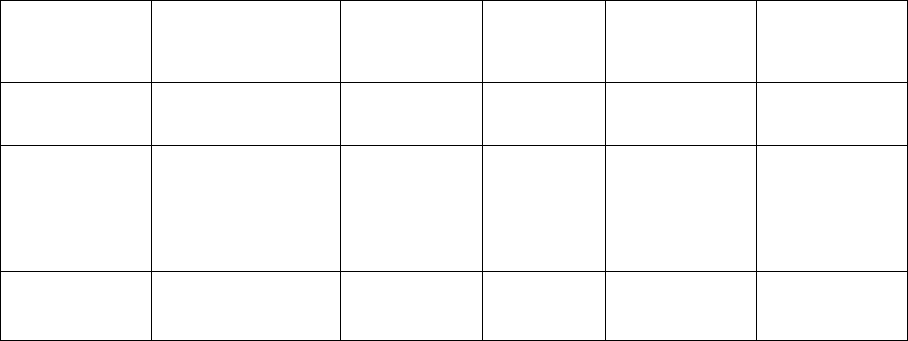

Equipment and Consumables

Listed in Table 1-3 are the equipment, consumables, and reagents needed to perform the

GARDskin assay.

Table 1 Equipment. Listed are the equipment used at the laboratory of the test method developers. Equipment for which a

specific manufacturer is not listed, the source of the equipment is considered arbitrary.

Equipment

Manufacturer

Sterile (LAF) hood for cell culture work, Class II

-

Fume hood for handling of chemicals

-

Heating block for small tubes (operating at 37°C±5°C)

-

Laboratory grade scale, capacity of weighing a minimum of 10 mg with reproducibility

-

Vials for long-term storage of cells in liquid nitrogen

-

2 separate CO

2

incubators (one for cell line culturing and one for chemical stimulation)

-

Benchtop centrifuge, swing-out rotor, 2-8°C, including adapters for 5/15/50 ml tubes

and adapters for 96 well plates

-

Freezer (operating at-18°C to -22°C)

-

Ultra-low freezer (operating at -70°C to -90°C)

-

Refrigerator (operating at 2-8°C)

-

Flow cytometer (minimum equipped with a blue laser, e.g. FACSVerse)*

E.g. BD

Microcentrifuge for 1.5 ml micro tubes

-

Minicentrifuge for 0.2 ml tubes

-

BioAnalyzer 2100*

E.g. Agilent

nCounter MAX, FLEX or sprint system**

NanoString

Thermocycler

-

Centrifuge adapters for 96 well plates

-

Pipetting controller

-

Pipettes 0.1-1000 µl

-

Good to have: Electronic multi-dispenser pipette 1 µl-50 ml

Good to have: Vacuum system for aspiration of cell supernatant and other liquid waste.

-

* The flow cytometer and BioAnalyzer could be exchanged for an equivalent instrument.

**The endpoint analysis is performed with an nCounter instrument, either at the Test Faciliy or at a NanoString

Facility if not available in-house.

GARDskin Page 8 of 41

Table 2. Consumables Listed are the consumables used at the laboratory of the test method developers. The exchange of any

of these articles for an equivalent product should not interfere with the protocols and/or results, but needs to be assessed to

ensure equivalence, especially the cell culture plastics.

Product

Company*

Catalog Number

TC Flask, 175 cm

2

Corning

431080

TC Flask, 75 cm

2

Corning

430641U

TC Flask, 25 cm

2

Corning

430372

Centrifuge tube, 15 ml

Corning

Sarstedt

430791

62.554.502

Centrifuge tube, 50 ml

Corning

Sarstedt

430829

62.547.254

12-well plate

Corning

3512

24-well plate

Corning

3524

Stripettes, 5 ml

Corning

Sarstedt

4051

86.1253.001

Stripettes, 10 ml

Corning

Sarstedt

4101

86.1254.001

Stripettes, 25 ml

Corning

Sarstedt

4251

86.1685.001

Stripettes, 50 ml

Corning

Sarstedt

4501

86.1256.001

Positive displacement pipette tips, 1 ml

Eppendorf

0030089642

Positive displacement pipette tips, 5 ml

Eppendorf

0030089669

Positive displacement pipette tips, 10 ml

Eppendorf

0030089677

Positive displacement pipette tips, 25 ml

Eppendorf

0030089685

Positive displacement pipette tips, 50 ml

Eppendorf

0030089693

Sterile and RNase-free filter tips 0.1-1000 µl

Sartorius (SafetySpace)

Biotix (uTIP)

Several

Cryogenic Vial

Corning

430488

Sample tubes for Flow cytometry

Corning

352052

(Deep 96 well plate if used for flow cytometry)

Corning

3960

0.2 µm sterile filter

Sarstedt

83.1826.001

Syringe Luer, 50 ml

Henke-Sass Wolf

8300006680

1.5 ml micro tubes

Sarstedt

72.690.001

RNase-free 1.5 ml micro tubes

Axygen

311-09-051

(RNase-free 2 ml vials in 96 racks if used for

homogenized cell samples)

Micronic

MP42150

RNase-free 0.2 ml tubes

Sarstedt

72.991.002

Nitrile gloves, thickness 0.14 mm

Shieldskin

67625

GARDskin Page 9 of 41

Table 3. Reagents. The listed producers are made available as a guidance for quality of listed reagents. The exchange of any of

these articles for an equivalent product should not interfere with the GARDskin assay, but needs to be assessed to ensure

equivalence. The NanoString products, are specifically required in this protocol and equivalent reagents do not, at this time,

exist.

Product

Company

Catalog Number

Cell Medium

MEM/Alpha Modification with L-glut, Ribo-& Deoxyribo

Cytiva

SH30265.01

Fetal Bovine Serum (FBS)** (Gibco)

Life Technologies

10270106

rhGM-CSF (Premium grade. Purity >97%, endotoxin

level <0.1 EU/μg cytokine, and activity of ≥5x10

6

IU/mg)

Miltenyi Biotec

130-093-868

Buffers & Solvents

D-PBS, HyClone

or D-PBS, Gibco

Cytiva

Life Technologies

SH30028.02

14190144

Bovine Serum Albumin (BSA), Cohn fraction V

Saveen & Werner AB

B2000

TRIzol Reagent

or TRI Reagent

Ambion

Thermo Fisher Scientific

15596018

AM9738

Ethanol, 95-100%, Undenatured

Solveco

1065

Antibodies & Staining

Mouse anti-human CD86-FITC

BD

555657

Mouse anti-human HLA-DR-FITC

BD

347400

Mouse anti-human CD34-FITC

BD

555821

Mouse anti-human CD1a-FITC

Agilent Dako

F714101-2

Mouse anti-human CD54-PE

BD

555511

Mouse anti-human CD14-PE

Agilent Dako

R086401-2

Mouse anti-human CD80-PE

BD

340294

Mouse polyclonal anti-IgG1-FITC

BD

555748

Mouse polyclonal anti-IgG1-PE

BD

555749

Propidium Iodide, 50 µg/ml

BD

556463

Trypan Blue Solution, 0.4%

Thermo Scientific

15250061

Reagents & Kits

Direct-zol RNA MiniPrep

Zymo Research

R2052

RNA 6000 Nano Kit

Agilent

5067-1511

nCounter MAX or Sprint consumables

NanoString

See nanostring product

information.

GPS200_v2 CodeSet (GARDskin)

NanoString

(Contact SenzaGen)

Chemicals and solvents

CAS no

Catalog no**

p-Phenylenediamine (PPD)

106-50-3

965106

DMSO ≥99.5%

67-68-5

D5879

Acetone

67-64-1

34850

Ethanol, 95-100%

64-17-5

-

Dimethylformamide

68-12-2

1.03053

Isopropanol

67-63-0

I9516

Glycerol

56-81-5

G5516

* Each lot of FBS needs to be assessed for cell culture compatibility.

** Catalog numbers at Sigma-Aldrich for guidance of e.g. purity of each chemical.

GARDskin Page 10 of 41

Media and Endpoint Assay Solutions

Serum, GM-CSF and antibodies

Prior to performing a GARDskin assay, FBS needs to be assessed and antibodies need to be

titrated (see Annex 1. FBS assessment and Annex 2. Antibody titration). The FBS can be

aliquoted and stored long-term at -18°C or below. The GM-CSF working stock (150 µg/ml)

should be prepared, aliquoted, and stored long-term at -18°C or below. The GM-CSF working

stock can be stored short-term at 2-8°C for maximum 1 week.

Cell mediumCell culture medium is prepared in two steps and referred to as follows:

1) Semi-complete medium

MEM/Alpha supplemented with FBS (20%).

Use within 30 days from supplementing FBS. Store at 2-8°C.

2) Complete medium

Semi-complete medium supplemented with GM-CSF (40 ng/ml).

0.26 µl GM-CSF(150 µg/ml) is added per ml semi-complete medium.

Complete medium cannot be stored and should be used directly.

See Table 3 for GM-CSF purity, endotoxin level and activity.

Medium for freezing cells

The SenzaCell cell line is frozen and stored in liquid nitrogen (or in a cryogenic freezer) in

complete medium supplemented with DMSO to a final DMSO concentration of 10%.

Flow cytometry Wash buffer

For all washing and staining steps and for suspension of cells prior to flow cytometry run, use

flow cytometry wash bugger: D-PBS supplemented with ~0.5-1% (w/w) BSA. The BSA is

dissolved in a smaller volume of D-PBS, which is filtered using a 0.2 µm filter prior addition to

the D-PBS. The prepared Wash buffer can be stored at 2-8°C for 30 days.

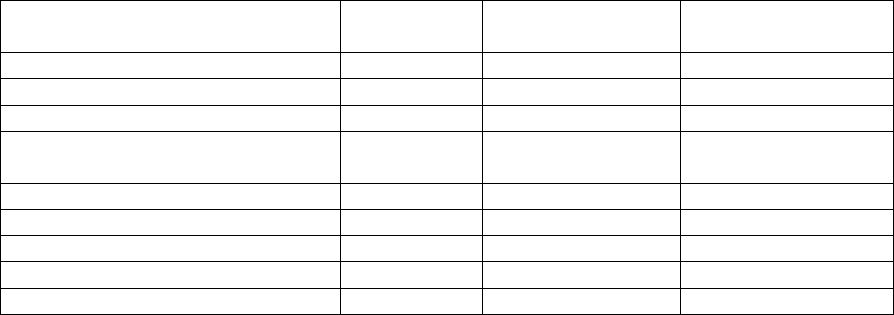

Summary of storage conditions for cell reagents.

Table 4: Storage conditions of routine cell culture and flow cytometry reagents.

Reagent

Storage long term

Storage short term

Assessment/titration

FBS

-18 °C or below until

expiry date.

2-8 °C for at least 30

days.

yes

GM-CSF

-18 °C or below until

expiry date.

2-8 °C for at least 7

days.

no

Antibodies

2-8 °C until expiry date.

Not applicable

yes

MEM/alpha

2-8 °C until expiry date.

Not applicable

no

Semi-

complete

medium

2-8 °C for 30 days

2-8 °C for 30 days

no

Complete

medium

Not applicable

Use same day as

mixing.

no

Flow

cytometry

wash buffer

Not applicable

2-8 °C for 30 days

no

GARDskin Page 11 of 41

Flow cytometer instrument setup

Prior to performing the GARDskin assay for the first time, a fluorescence compensation of the

flow cytometer should be performed. The compensation should be performed according to the

specific instrument . In flowcytometry, “Compensation” is a mathematical correction of a signal

overlap between the channels of the emission spectra of different fluorochromes. In the

GARDskin assay , the compensation should preferably be performed using the SenzaCell cell

linesingle stained with the mAbs HLA-DR-FITC and CD54-PE. For flow cytometry analysis,

appropriate flow rate should be set (FACSVerse 60-120 µl/min).

Controls

For each GARDskin test, relevant controls are analyzed in each of the three replicate GARD

Main Stimulations. The controls are listed in Table 5, with relevant information for the

laboratory work. The GARDskin input concentration of the positive control,

p-Phenylenediamine (PPD), should be determined in a cytotoxicity assessment while

establishing the method in the laboratory. The input concentration for PPD should be the same

independent of operator at the same laboratory.

Table 5. List of controls used in the GARDskin assay.

Substance ID

Control

GARDskin

classificatio

n

Solvent

GARD Input

conc (µM)

Viability

pos ctrl

p-Phenylenediamine

(PPD)

Sensitizer

DMSO

As determined

in cytotoxicity

assessment.

84.5 - 95.4%

(Relative

Viability)

neg ctrl

Test chemical

vehicle*

Non-sensitizer

Not

applicable

Concentration

corresponding

to vehicle

concentration in

test chemical

stimulation well*

≥95.5%

(Relative

Viability)

unstim ctrl

No stimulant added

beside complete cell

culture medium

Not applicable

Not

applicable

Not applicable

≥84.5%

(Absolute

Viability)

*See Table 8 on page 18 for available vehicles and corresponding maximum concentration.

Unstimulated controls

The unstimulated control is used for determination of absolute and relative cell viability of cell

batches and for normalization purposes in the Data analysis workflow.

Negative controls

The negative control is a vehicle control to verify that cells have not become activated in any

steps of the method’s experimental procedures, i.e. the vehicle shall not induce cytotox and

shall be classified as a non-sensitizer.

Positive controls

The positive control shall verify that the cells are responsive and can become activated upon

exposure of a skin sensitizer, i.e. the positive control shall induce cell cytotoxicity and be

classified as a sensitizer

GARDskin Page 12 of 41

Demonstration of Proficiency

According to OECD TG 442E GARDskin assay laboratories should demonstrate technical

proficiency in using the test method prior to routine use of GARDskin. Proficiency is

demonstrated by testing of a specified set of proficiency chemicals with known sensitising

properties, as listed in Table 6.

Table 6. Substances for demonstrating technical proficiency with GARDskin.

Proficiency substances

CASRN

Reference value

1

GARDskin

prediction

4-nitrobenzyl bromide

100-11-8

Sensitiser

Sensitiser

Propyl gallate

121-79-9

Sensitiser

Sensitiser

Isoeugenol

97-54-1

Sensitiser

Sensitiser

3-(Dimethylamino)-1-

propylamine

109-55-7

Sensitiser

Sensitiser

Eugenol

97-53-0

Sensitiser

Sensitiser

Ethylene glycol dimethacrylate

97-90-5

Sensitiser

Sensitiser

Glycerol

56-81-5

Non-sensitiser

Non-Sensitiser

Hexane

110-54-3

Non-sensitiser

Non-Sensitiser

1-Butanol

71-36-3

Non-sensitiser

Non-Sensitiser

1

NICEATM LLNA database 2010.

Method

Routine Procedures

All cell work should be performed under sterile conditions free of antibiotics; work in a

laboratory designed for growth of mammalian cells, use LAF-workbenches and sterile

consumables.

All cell centrifugation steps are performed at 300-315xg, 5 min, 2-8°C. All cell incubations are

performed in cell incubators at 37°C1°C and 5%0.5% CO

2

at saturated humidity.

Cell cultures should not be grown for more than 16 passages (~ 2 months) after thawing. A

cell passage is defined for SenzaCell cells as each time the cell culture is counted and split,

independently of how the cells has grown i.e. its doubling time (see below sections Thawing of

cells for details about cell passage numbering, and Cell seeding for test chemical stimulation

for details about the range of cell passages used in cell stimulation).

For cell maintenance, grow cells in cell culture flasks. For volumes up to 10 ml, use TC Flask

25 cm

2

. For volumes of 10-45 ml, use TC Flask 75 cm

2

. For volumes of 40-120 ml, use TC

Flask 162-175 cm

2

. Note that for large cultures, more than one TC 162-175 cm

2

may be

required.

Thawing cells

The SenzaCells are stored in liquid nitrogen (liquid phase) or in a cryogenic freezer, 7 million

cells /ml complete medium supplemented with 10% v/v DMSO.

- Thaw the cells by submerging the bottom half of the frozen vial in a ~37°C

water.

GARDskin Page 13 of 41

- Add 10 ml semi-complete medium to a 15 ml tube and transfer the thawed cells

to the tube. Centrifuge the cells.

- Remove supernatant by decantation. Resuspend the cell pellet in 5 ml semi-

complete medium. Add 0.26 µl GM-CSF per 1 ml of cell suspension to the cell

culture.

- Move the cells to a small cell culture flask (TC Flask 25 cm

2

) and incubate the

cell culture (i.e. cell passage number P0).

- The next day, transfer the cell culture from the cell culture flask to a 50 ml tube.

Centrifuge.

- Remove supernatant by decantation. Resuspend in 1 ml semi-complete

medium.

- Count the cells. Resuspend the cell culture in semi-complete medium to a

volume corresponding to a cell concentration of 2 x 10

5

cells /ml.

- Add 0.26 µl GM-CSF per 1 ml of cell suspension to the cell culture. Incubate the

cell culture (i.e. cell passage number P1).

Cell batches

For convenience, it is preferred to run three cell batches in parallel. Within the GARDassay, a

unique cell batch is defined as follows.

- cells originating from different frozen vials, or,

- cells originating from the same frozen vial, which have been cultivated

separately. A division of cell cultures for the purpose of achieving separate cell

batches should be done no sooner than passage 3 after thawing, and no later

than at least 2 passages prior to exposure experiments.

Cell Propagation

Every 3-4 days the cells are counted and propagated to 2 x 10

5

cells /ml in fresh medium. The

cell propagation is preferably performed on Mondays and Thursdays to coincide with cell

stimulations (see Cell seeding for test chemical stimulation).

- To split the cells, transfer the cell culture from cell culture flasks to appropriate

tubes. Centrifuge.

- Remove supernatant by decantation. Resuspend the cells in an appropriate

volume of semi-complete medium (the volume is dependent on the system used

for counting the cells).

- Count the cells.

- Resuspend the cell culture in semi-complete medium to a volume corresponding

to a cell concentration of 2 x 10

5

cells /ml.

- Add 0.26 µl GM-CSF (150 µg/ml) per 1 ml of cell suspension to the cell culture.

- Incubate in cell culture flasks.

Cryopreservations

- To freeze the cells, transfer the cell culture from cell culture flasks to 50 ml tubes

and centrifuge.

- Remove supernatant by decantation. Resuspend the cells in an appropriate

volume of semi-complete medium.

- Count the cells. Resuspend the cell culture in semi-complete medium to a

volume corresponding to a cell concentration of 14 million cells /ml.

- Add 0.26 µl GM-CSF (150 µg/ml) per 1 ml of cell suspension to the cell culture

(final GM-CSF is 40 ng/µl)

- Prepare a solution of complete medium supplemented with 20% v/v DMSO.

GARDskin Page 14 of 41

- Transfer 0.5 ml of cell suspension to cryogenic vials (marked with cell bank

identity, i.e. name of cells, date of freezing, type of cell bank stock).

- Add 0.5 ml of DMSO-supplemented complete medium to each of the cell-

containing cryogenic vials, close the lids and invert the vials to mix.

- Immediately freeze the cells slowly in a temperature-controlled manner (-

1°C/min down to -70 – -90°C).

- Vials are submerged into liquid nitrogen for long-term storage.

Preparing Flow cytometry samples

All washing steps are performed in Wash buffer. All centrifugations are performed at 300-

315xg, 5 min, 2-8°C. All incubations are performed in dark at 2-8°C. Each lot of mAbs needs to

be titrated to determine antibody concentration giving saturation (see Annex 2. Antibody

titration).

Phenotypic Quality Control

The same day as performing a chemical stimulation, the cells are quality controlled with a

phenotypic analysis. This is done to ensure cells are maintained in an inactivated state and to

detect phenotypic drift.

Count cells and prepare 6 flow cytometry samples, with 2 x 10

5

cells in each sample.

- Wash the cells by adding 1 ml Wash buffer and centrifuge at 300-315xg, 5 min,

2-8°C.

- Remove the supernatant by aspiration and repeat the washing step. Resuspend

in 50 µl Wash buffer.

- Stain cells as indicated in Table 5 by adding titrated mAbs or viability stain to

each sample.

Table 5. Antibodies and viability stain used in the Phenotypic Quality Control.

Sample 1

Isotype FITC

Isotype PE

Sample 2

CD86-FITC

CD54-PE

Sample 3

HLA-DR-FITC

CD80-PE

Sample 4

CD34-FITC

CD14-PE

Sample 5

CD1a-FITC

Sample 6

Propidium Iodide (PI)

- Incubate in dark at 2-8°C for 15 min.

- Wash the cells by adding 1 ml Wash buffer and centrifuge the samples at 300-

315xg, 5 min, 2-8°C.

- Remove the supernatant by aspiration, resuspend in appropriate volume Wash

buffer (using the mAbs and flow cytometer suggested in this protocol, 200 µl is

used).

Analyze the samples on a flow cytometer according to manufacturer’s instructions (for

FACSVerse, use flow rate 60-120 µl/min) Record approximately and at least 10,000 events

and analyze using the gating instructions below.

Note:

• Removal of supernatant during preparation of flow cytometry samples is done by

aspiration, e.g. by pipetting or by using a vacuum system, not by decantation.

GARDskin Page 15 of 41

Analysis of Cell population

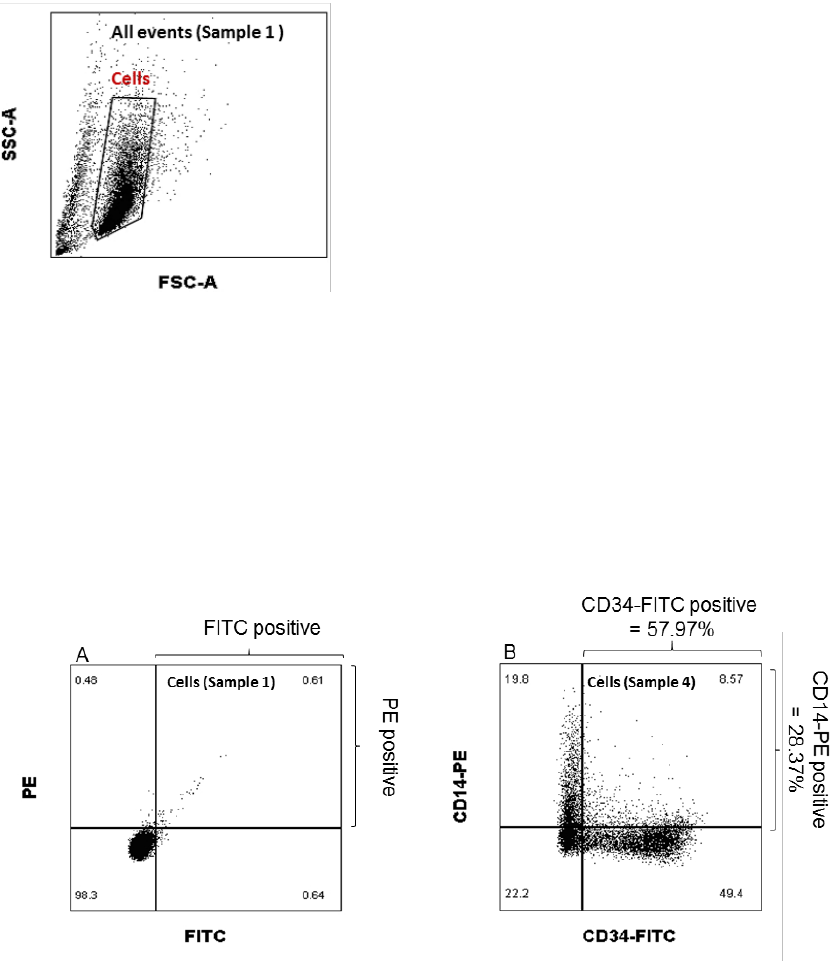

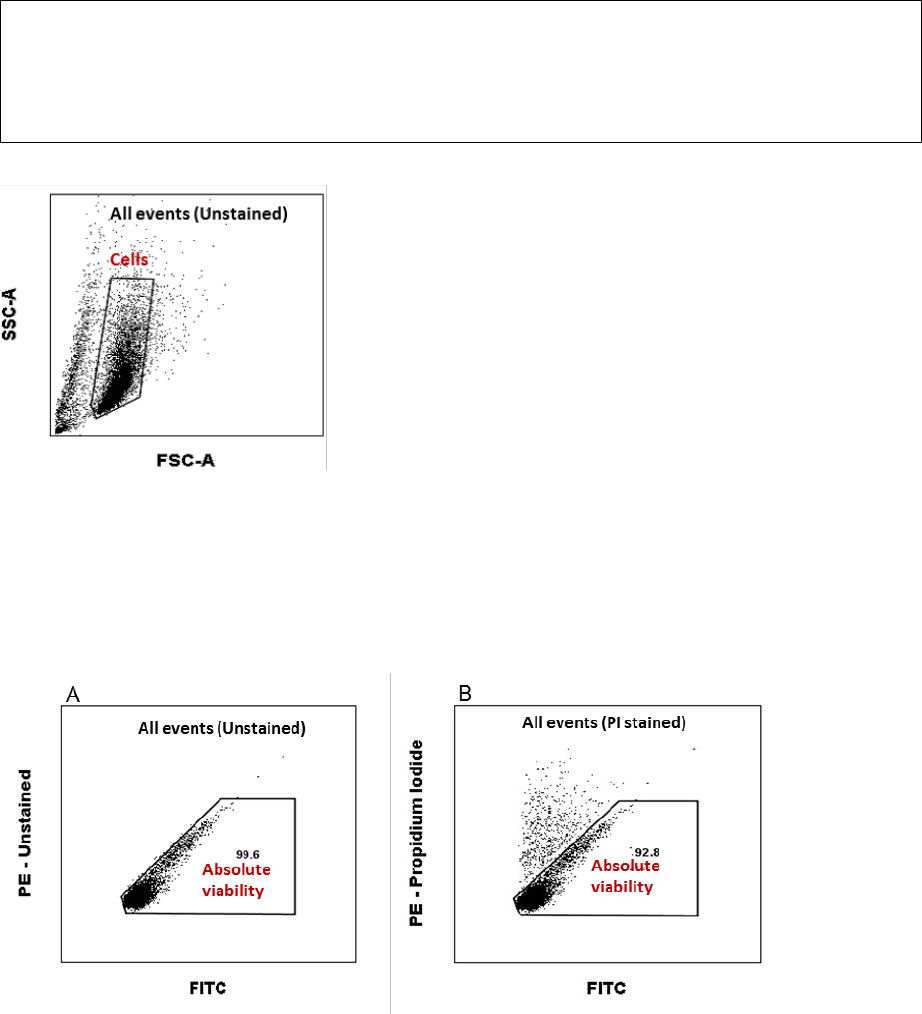

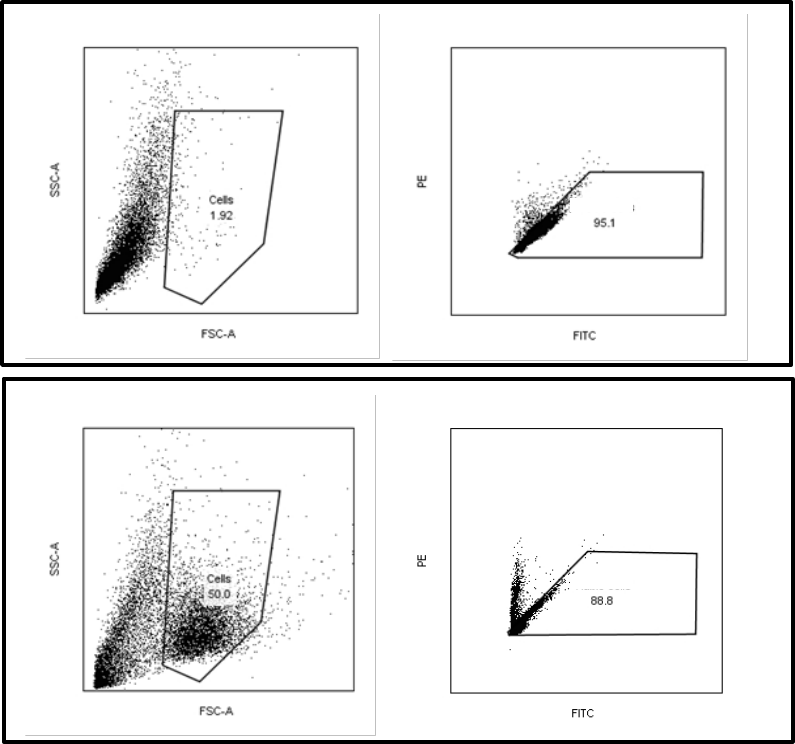

Exclude dead cells and cell debris by setting the “Cells” gate in the FSC-A/SSC-A scatter plot

using Sample 1 (Isotype control), see Figure 2. Apply the “Cells” gate on Sample 2-6.

Figure 2. Instructions for setting the gate for the SenzaCell cell population.

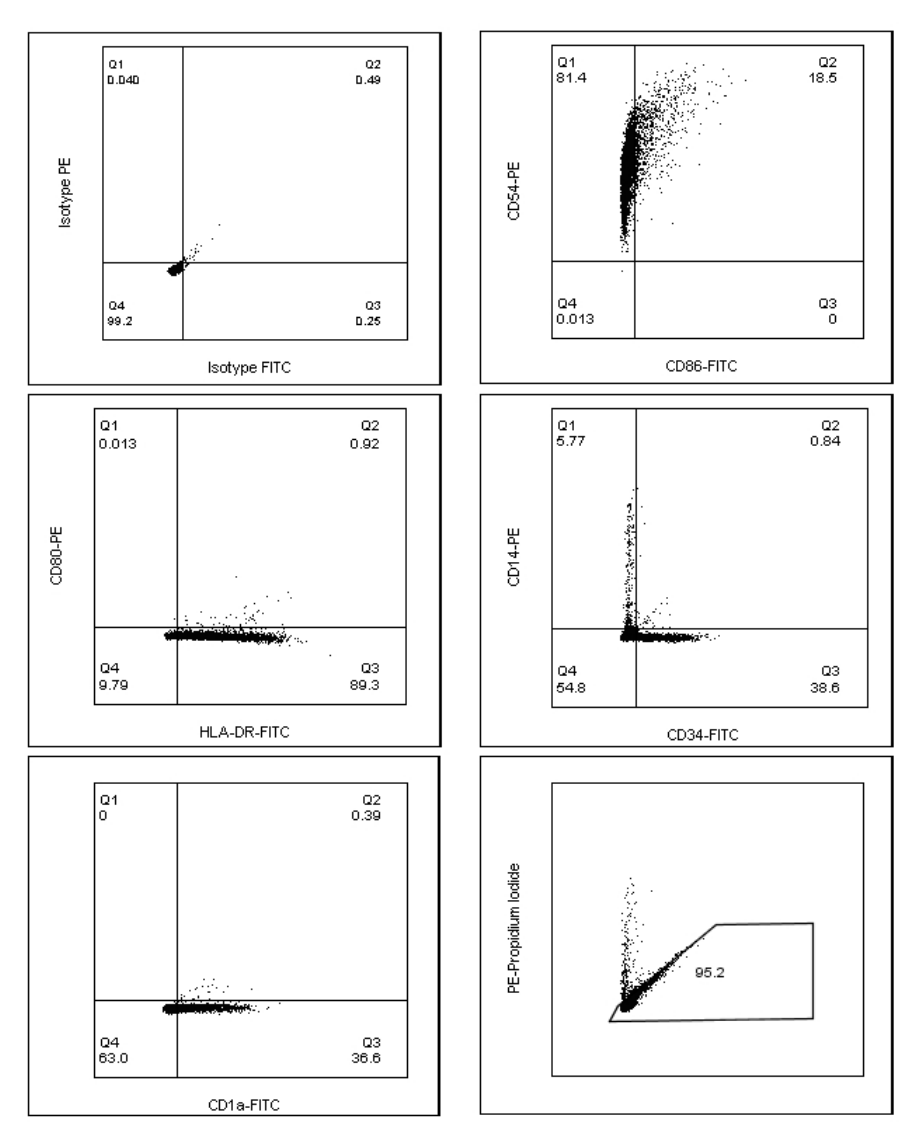

Analysis of Phenotypic Quality Control markers

Show the gated “Cells” population in a PE/FITC scatter plot. Set quadrants for PE and FITC

positive and negative cells using Sample 1 (isotype controls) as Figure 3A. Apply the quadrant

from the isotype control sample in a PE/FITC scatter plot showing the “Cells” population of

Sample 2-5 (mAb stained). Calculate and record the fraction of PE and FITC positive cells for

each phenotypic marker, see example of Sample 4 below in Figure 3B, and compare with the

accepted range in Table 6.

Figure 3.. Instructions for setting the quadrants for PE and FITC positive cells (A). Apply the preset gate and quadrants to

record the fraction of positive cells for each phenotypic marker (B).

Analysis of Absolute viability (PI negative cells)

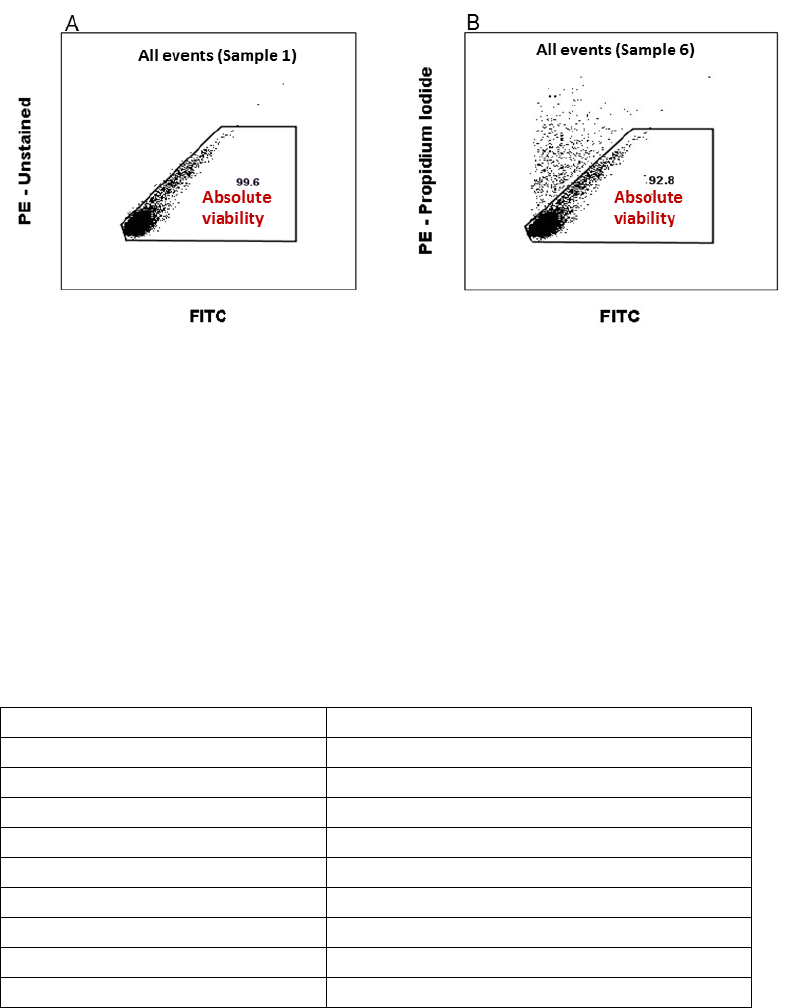

Set the gate for “Absolute viability”, in the PE/FITC scatter plot showing “All events” on Sample

1 (Figure 4A). Apply the “Absolute viability” gate on Sample 6 (PI stained), as in Figure 4B.

Record the fraction of “Absolute viability” in % (PI negative cells) from Sample 6 and compare

with the accepted range in Table 9.

GARDskin Page 16 of 41

Figure 4 Instructions for setting the gate for “Absolute viability”on the Isotype stained sample (A). Apply the gate “Absolute

viability” on Sample 6 (B).

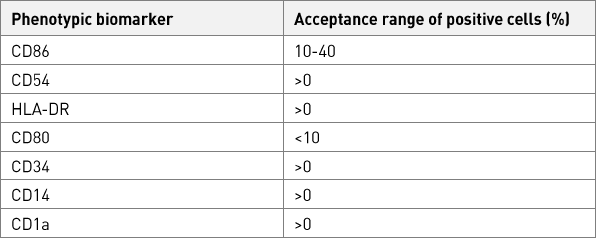

Phenotypic Quality Control acceptance criteria

The accepted range of phenotypic biomarker expression (Table 7) is based on observations

made in the developing laboratory during assay development. Variations within these ranges

are to be considered normal. However, if any of the biomarkers are out of the specified

ranges, it is recommended that the cell batch is not used for cell stimulations at that timepoint.

A representative example of a typical SenzaCell phenotype is presented in Annex 3.

SenzaCell Phenotype. Note that the cell line is known to be heterogenous, and variations

within the accepted ranges from given examples are expected.

Table 7. Accepted range for phenotypic markers of the SenzaCell cells.

Phenotypic biomarker

Accepted range of positive cells (%) *

CD86

10-40

CD54

>0

HLA-DR

>0

CD80

<10

CD34

>0

CD14

>0

CD1a

>0

Phenotypic biomarker

Accepted range of PI negative cells (%)

Absolute viability (PI negative cells)

≥84.5

Cell seeding for Test chemical stimulations

Cells are seeded for stimulation directly following a cell split, i.e. test chemical stimulations are

to be scheduled to coincide with routine cell culture maintenance. This has been noted by the

GARDskin assay developers to be an important factor. The cell stimulations are initiated when

a stable cell culture is established i.e. when at least a duplication of the cells between cell

passages is seen, and depending on the purpose of the cell stimulation, at specific cell

passage ranges:

- For cytotoxicity assessment, cells at passage number P4-P16 are used.

- For GARD Main Stimulation, cells at passage number P6-P12 are used.

GARDskin Page 17 of 41

Test Chemical Stimulation Procedures

Handling of the test chemical

A chemical that is to be tested for sensitization in the GARDskin assay is referred to as a “test

chemical”. The test chemical should be stored according to instructions from the supplier, in

order to ensure its stability. Weighing of the test chemical can be performed prior to the day of

cell stimulation if stored correctly and the stability of the substance can be ensured. Dissolved

test chemical should be prepared fresh on the day of cell stimulation. Test chemicals should

be dissolved in a compatible vehicle as appropriate stocks of target in-well concentration, in

this document referred to as a Stock A concentration, depending on maximum possible

solvent in-well concentration.

To prepare a solid test chemical, calculate the weight (see Note below about minimum weight

of the scale) needed for an appropriate volume according to Equation 1. The test chemical is

weighed into a pre-tared micro tube or appropriate vessel. Based on the weighed amount,

calculate the exact volume of solvent needed to reach the c

T

, according to Equation 1.

(Equation 1)

Where

V is the volume to be added in L

m is the exact weight added to the tube in g

M is the molecular weight of the test chemical in g/mol

p is the purity of the test chemical in %

c

T

is the desired target concentration in mol/L

To prepare a liquid test chemical, use Equation 2 to calculate a dilution factor and calculate

the volume of the test chemical and solvent needed for an appropriate volume of the test

chemical of Stock A. Dilute the stock by the dilution factor into a 1.5 ml micro tube in the

appropriate solvent.

(Equation 2)

Where

df is the dilution factor

c

S

is the concentration of the stock in mol/L

c

T

is the desired target concentration in mol/L

Note:

• A test chemical is preferably to be defined by a known molecular weight, as appropriate

GARD Input Concentration are defined by molar concentrations. However for complex

mixtures of unknown composition, substances of unknown or variable composition, complex

reaction products or biological materials this may not be possible. However, this limitation

may be circumvented by a) the use of weight-based concentrations (ppm), since the vast

majority of sensitizers are detected at <100 ppm of the GARDskin assay (Gradin et al..), or b)

by an approximation of the mean molar weight of the complex mixture.

• If the molar concentration of a liquid test chemical is not given by the customer, calculate the

molar concentration using the molecular weight, density and purity of the test chemical.

• If the density of a liquid test chemical is not available, weigh the test chemical.

• If the substance is too viscous for pipetting, weigh the test chemical.

GARDskin Page 18 of 41

Solubility assessment

Consider the physiochemical properties of the test chemical and use the GARDskin

compatible solvents and their maximum in-well concentrations listed in Table 7.

DMSO or water is the preferred vehicle. If neither is suitable, e.g. the test chemical is not

dissolved, unfavourable reactions are expected, or other reasons, then a different vehicle can

be tested. Independent of vehicle, a 2-step dilution is tested first, if not suitable then the 1-step

dilution is tested. In some cases, where the test chemical has high reactivity with water or

other unfavourable reactions are expected, a 1-step dilution can be tested first. Solubility of

Test Items should be evaluated at least by a visual inspection of the solution. The Test Item is

considered dissolved when the solution is without precipitate or phase separations. Other

solubility approaches may also be used to reach dissolved test chemicals.

2-step dilution

Stock A

- Prepare a Stock A with a c

T

(desired target concentration of the test chemical) of 500

mM.

- Vortex extensively and apply heat (37 ±5 °C), if necessary, to dissolve the test

chemical.

- Sonication may also be used if necessary and if compatible with the substance.

- If not soluble: The stock A 500 mM maximum limit is specified for a vehicle

concentration of 0.1% in well, if a higher vehicle concentration can be used (see

Table 4) then lower the concentration accordingly (see Table 2) to achieve an in

well concentration of 500 μM. If soluble, proceed to the last step below. If the

Test Item is not soluble at a concentration corresponding to 500 μM in-well in

any vehicle, identify the highest possible concentration where the Test Item is

soluble in a suitable vehicle. Use the highest soluble concentration as a starting

point in the dilution range.

- Perform a serial dilution in the chosen vehicle to get a suitable range of stock A

concentrations. Vortex well between each step. An example dilution scheme

when working with a substance freely soluble at 500 mM in vehicle and at 500

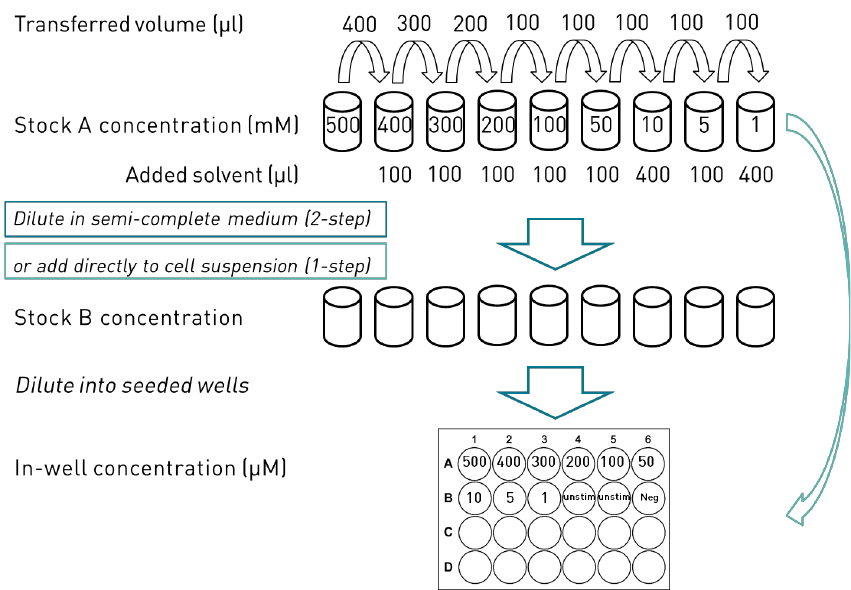

μM in medium is seen in Figure 5 on page 21.

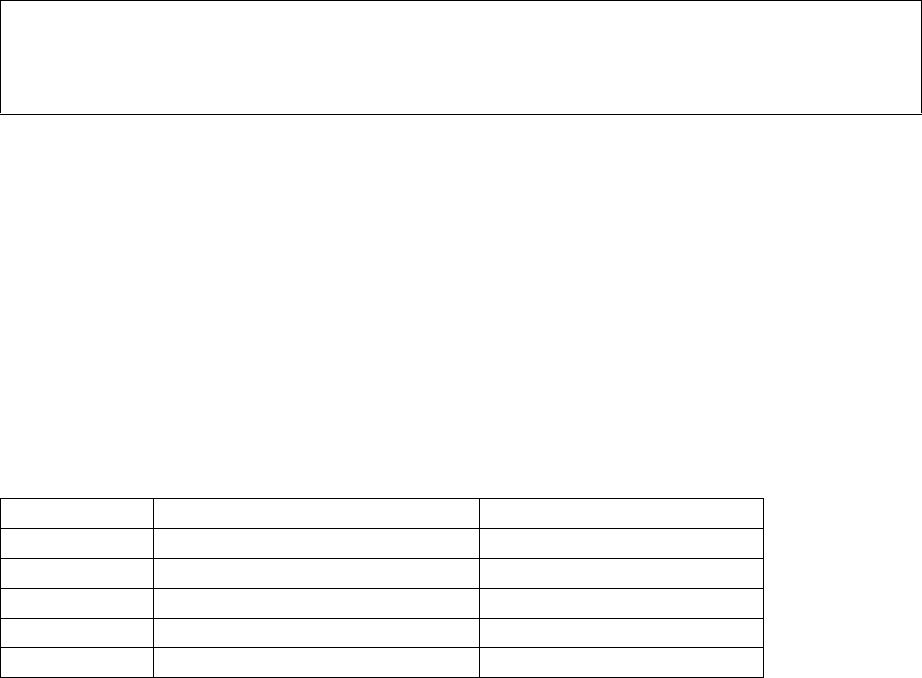

Table 8 . The GARDskin compatible vehicles and the highest in-well concentrations. In the validation study only

water and DMSO at 0.1 % were used. Other vehicles and vehicle concentrations have been verified to work in the

GARDskin assay by the developing laboratory.

Vehicle*

Max in-well concentration (%)

DMSO

0.5

Water

0.1

Acetone

0.1

DMF

0.1

EtOH

0.1

Glycerol

1

Isopropanol

0.25

DMF:Glycerol 4:1 (v/v %)

0.25

Complete medium

100

*All the vehicles should be of high grade (purity ≥99.5%).

GARDskin Page 19 of 41

Serial dilution

- Perform a serial dilution in the chosen solvent to get a range of Stock A concentrations

(see example in Figure 5). Vortex well between each dilution step. Extensive vortex and

heat (37°C±5°C) can be applied.

- From Stock A, prepare a range of Stock B concentrations by adding appropriate

volume of Stock A to semi-complete medium. Extensive vortex and heat (37°C±5°C)

can be applied. If the substance is poorly soluble in semi-complete medium (typically

identified through observation of precipitation in Stock B), the highest soluble

concentration in semi-complete medium is used as the highest in the dilution range.

- In addition, prepare a Stock B concentration of chosen solvent (neg ctrl) in semi-

complete medium to achieve the corresponding in-well concentration of the solvent.

1-step dilution

If a test chemical has a maximum solubility in Stock B which is lower than expected with

respect to the maximum solubility in Stock A (i.e. displays solubility issues in Stock B), and is

found to be non-toxic, i.e. the relative viability is above 95.4 %, the operator can try to

increase the in-well concentration by bypassing the Stock B step as follows:

1. Prepare Stock A at the maximum possible concentration and prepare a serial dilution.

2. Add appropriate volume of Stock A dilution directly to complete medium.

3. Note the highest possible test chemical concentration in complete medium that does

not have solubility issues i.e. completely solved.

4. If the highest possible concentration is higher than that in Stock B, prepare cells as

described in ‘cell seeding’ in the sections below.

Cytotoxicity Assessment

The GARDskin Input concentration can be established for the test chemical in a cytotoxicity

assessment. For an efficient workflow, multiple test chemicals can be assessed in each

stimulation experiment with shared controls, unstim ctrl and neg ctrl, which are included in

each cytotoxicity assessment. The cytotoxicity assessment results are used as guidance to

find the appropriate stimulation concentration to be used during the Main Stimulations.

To determine the GARDskin Input concentration for a test chemical, cell stimulations are

performed in a range of in-well concentrations as determined appropriate based on solubility

assessment. For details about weighing and calculation, see section Handling of the test

chemical.

Day 1

Cell seeding

The below cell seeding protocol is an example of the cell seeding when using a two-step

dilution of the test chemical. If other dilutions schemes are used, use another seeding practice,

but make sure the final cell concentration in-well after addition of the test chemical is 2 x 10

5

cells /ml.

Note:

• Make sure to secure the lids before heating and vortexing the test chemical.

• A test chemical with solubility issues should be used from the highest possible

concentration, down to 1 µM in-well concentration of the dilution range.

GARDskin Page 20 of 41

- Transfer the cell culture from cell culture flasks to appropriate size tubes (e.g. 50 ml

tubes). Centrifuge at 300-315xg for 5 min at 2-8°C.

- Remove the supernatant by decantation. Resuspend the cells in an appropriate volume

of semi-complete medium.

- Count the cells.

- Resuspend the cell culture in semi-complete medium to a volume corresponding to a

cell concentration of 2.2 x 10

5

cells /ml (final cell concentration in wells after addition of

test chemical will be 2 x 10

5

cells /ml). Add 0.26 µl GM-CSF (150 µg/ml) per 1 ml of cell

suspension to the cell culture.

- Use 24-well plates and seed 1.8 ml of cell suspension into the number of wells needed

(see Figure 5).

Cell stimulation

For each cell stimulation, independent of number of test chemicals and number of plates, it is

recommended to include two wells of unstimulated cells (unstim ctrl) and one well with the

vehicle (negative control) (Figure 5). If the test chemicals are dissolved using different

solvents, each solvent should be present as negative controls. If several different

concentrations of one solvent are used, it is sufficient to use the highest concentration as

negative control in this experiment.

- Test chemical: add 200 µl of Stock B to the 1.8 ml cell suspension seeded in 24-well

plates for the dilution range of each test chemical. Mix well by pipetting. Final cell

concentration in wells is 2 x 10

5

cells /ml.

- Example for 1-step dilution: If the final vehicle concentration should be 0.1% use the

following method:

o Add 2 µl of each Stock A dilution that did not have solubility issues in complete

medium to wells containing 1.8 ml cells.

o Add 198 µl semi-complete medium to the same wells and mix by pipetting.

- Negative control: add 200 µl of relevant solvent Stock B to the 1.8 ml cell suspension

Example for 1-step dilution: If the final concentration should be 0.1% solvent use the

following method:

o Add 2 µl of solvent to wells containing 1.8 ml cells.

o Add 198 µl semi-complete medium to the same wells and mix by pipetting.

- Unstimulated control: add 200 µl of semi-complete medium to the 1.8 ml cell

suspension, to achieve an in-well cell concentration and total volume equivalent to test

chemical treated samples.

- Incubate for 24 h±0.5 h at 37°C1°C and 5%0.5% CO

2

.

Example of preparation of a serial dilution and a cytotoxicity assessment stimulation for one

test chemical is shown in Figure 5.

GARDskin Page 21 of 41

Figure 5. Example of a schematic description of preparation of dilution series of one test chemical for cytotoxicity assessment.

Day 2

Cell harvest and sample preparation

After 24 h±0.5 h incubation, harvest and prepare:

- Duplicate flow cytometry samples of each test chemical stimulation for the

dilution range.

- Duplicate flow cytometry samples of negative control.

- Four flow cytometry samples of unstimulated cells (unstim ctrl).

- Mix the cell cultures in each well by carefully pipetting up and down and split

into duplicate samples, ~1000 µl to each replicate. For the unstim ctrl four flow

cytometry samples should be generated; two for staining with PI and two for

non-staining. It is recommended to clearly mark the two samples which should

not be stained. If only one unstim ctrl well has been used, split this cell culture

into four flow cytometry samples.

- Wash the cells by adding ~1 ml Wash buffer and centrifuge.

- Remove the supernatant by aspiration, resuspend in ~1 ml wash buffer and

centrifuge.

- Prepare a staining solution (enough for 50 µl for each flow cytometry sample) of

50 µl Wash buffer and 1 µl Propidium Iodide (PI).

- Resuspend each sample in 50 µl of the staining solution. Note: Leave 2 (out of

4) samples with unstimulated cells unstained, resuspend them in 50 µl Wash

buffer instead.

- Incubate in dark at 2-8°C for ~10 min.

- Wash the cells by adding ~1 ml Wash buffer and centrifuge. Resuspend in a

suitable amount of Wash buffer (using FACSVerse: resuspend in 200 µl).

GARDskin Page 22 of 41

- Analyze the samples on a flow cytometer according to manufacturer’s

instructions(FACSVerse: flow rate 60-120 µl/min). Record approximately and at

least 10,000 events and analyze using the gating instructions below.

Analysis of Cell population

Exclude dead cells and cell debris by setting the “Cells” gate in the FSC-A/SSC-A scatter plot

using the unstimulated unstained sample, see Figure 6. Apply the “Cells” gate on all PI stained

samples and record fraction of “Cells”.

Figure 6. Instructions for setting the gate for the SenzaCells.

Analysis of Absolute viability (PI negative)

Use the unstimulated unstained sample to set the gate for “Absolute viability”, in the PE/FITC

scatter plot showing “All events” (Figure 7A). Apply the preset “Absolute viability” gate on all PI

stained samples as in Figure 7B. Record the fraction of “Absolute viability” in % (PI negative

cells).

Figure 7 Instructions for setting the gate for “Absolute viability” (A). Apply the gate “Absolute viability” on all PI stained

samples (B).

Note:

• The “Cells” population is not used for further analysis but is used to keep track of the

placement of the cell population in the FSC-A/SSC-A scatter plot, see Annex 4. Cell

population for a common pitfall. A low “Cells” population can give a false percentage

“Absolute viability”.

GARDskin Page 23 of 41

Once the fraction of Absolute viability in % for the entire dilution range of a test chemical has

been recorded, the Relative viability for each sample is calculated according to Equation 3. For

each concentration of the dilution range, calculate the mean value of the duplicate samples.

(Equation 3)

Where

Rv is the Relative viability of the sample in %

V

S

is the Absolute viability of the sample in %

V

C

is the mean Absolute viability of the two unstimulated PI stained control samples in %

The GARDskin input concentration of a test chemical is decided as following:

1. A test chemical that induces cytotoxicity should be used for GARDskin Main

Stimulation at the concentration that induces 90% Relative viability (Rv90), where an

acceptance criterion for each sample is a Relative viability of 84.5%-95.4%. If multiple

concentrations fulfill the acceptance criterion, the concentration that yields the Relative

viability closest to 90% is chosen as the GARDskin input concentration.

2. If the Relative viability decreases from ≥95.5% to <84.5% between two data points

within the dilution range, the cytotoxicity assessment is repeated with a number of data

points within the relevant concentration range. Interpolation between data points is not

recommended, as linearity cannot be assumed.

3. A test chemical that is not cytotoxic (Relative viability ≥95.5%) is used for GARD Main

Stimulation at 500 µM or highest soluble concentration.

GARDskin Main Stimulation

The purpose of the Main Stimulation is to generate three biological replicates of cell cultures

exposed to the test chemical. The three should have been stimulated with the same test

chemical concentration. However, in Main Stimulations several concentrations of the same

test chemical may be used. For example time restrictions may necessitate the cytotoxicity

assessment to coincide with the Main Stimulations.

The Main Stimulations should be performed three times with individual preparations of the test

chemicals and controls. Individual cell batches (see section Abbreviations and definitions)

should be used, to achieve three biological replicate samples (see Table 4 for details of the

controls). The chemical concentration to be used in this step could be determined during the

cytotoxicity assessment or directly in the main stimulation step where several concentrations

may be assayed. The three GARDskin Main Stimulations can either be run in parallel or

sequentially. If several test chemicals are to be analyzed in the same GARDskin experiment,

the controls can be shared. Prior to starting a Main Stimulation, it is recommended to assign

all Test and Reference Items to be tested a Study-unique Sample ID according to standard

procedure set up in the testing laboratory. Consult permissible characters for the endpoint

measurement CDF-files (NanoString technologies) and avoid incompatible characters in the

Sample ID. Use the Sample ID for the Main Stimulation and for further procedures.

Note:

• The controls should pass the viability acceptance criteria, see Table 4, unstim ctrl:

Absolute viability ≥84.5% and neg ctrl: Relative viability ≥95.5%.

GARDskin Page 24 of 41

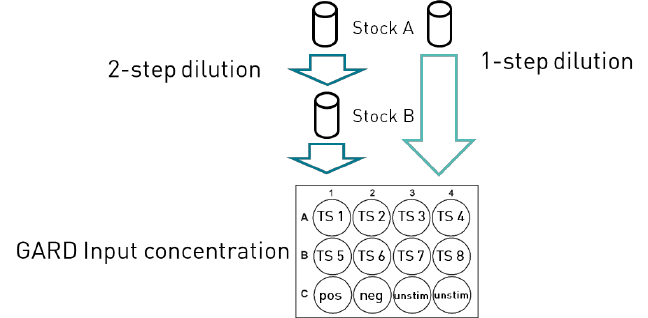

In Figure 8, a schematic example of a stimulation experiment with 8 test chemicals and the 3

controls are visualized, including one extra cell culture well with unstimulated controls.

Day 1

Preparation of test chemical and controls

- Prepare the test chemical in the same way as determined during solubility

assessment and cytotoxicity assessment.

- Take into account the increased volume, 4 ml final cell suspension, for the

stimulation.

- In addition, prepare the positive and negative control to achieve appropriate in-

well concentration.

Cell seeding

Below cell seeding protocol is an example of the cell seeding when using a two-step dilution of

the test chemical. If another dilution scheme was determined during solubility and cytotoxicity

assessment, other cell seeding practices apply. No matter how the test chemical is diluted, the

final cell concentration in wells after addition of test chemical should be 2 x 10

5

cells /ml.

- Transfer the cell culture from cell culture flasks to appropriate tubes. Centrifuge

at 300-315xg for 5 min at 2-8°C.

- Remove supernatant by decantation. Resuspend the cells in an appropriate

volume of semi-complete medium.

- Count the cells.

- Resuspend the cell culture in semi-complete medium to a volume corresponding

to a cell concentration of 2.2 x 10

5

cells /ml (final cell concentration in wells after

addition of test chemical will be 2 x 10

5

cells /ml). Add 0.26 µl GM-CSF (150

µg/ml) per 1 ml of cell suspension to the cell culture.

- Use 12-well plates and seed 3.6 ml of cell suspension into the number of wells

needed for test chemicals and controls (see Figure 8).

Cell stimulations

For each cell stimulation experiment, it is recommended to include two cell culture wells of

unstimulated cells (unstim ctrl). Below is, for convenience, described a test chemical standard

dilution. Since the test chemical preparation can differ this is only a recommendation and

guidance.

- Test chemical: add 400 µl of Stock B to the 3.6 ml cell suspension seeded in

12-well plates. Mix well by carefully pipetting up and down. Final cell

concentration in well is 2 x 10

5

cells /ml.

If the 1-step dilution method is used (example for 0.1 % vehicle in-well):

o Add 4 µl of each Stock A to wells containing 3.6 ml cell

suspension.

o Add 396 µl semi-complete medium to the same wells and

carefully pipette up and down to mix.

- Positive control: add 400 µl of Stock B to the 3.6 ml cell suspension.

- Negative control: add 400 µl of Stock B to the 3.6 ml cell suspension.

If the 1-step dilution method is used and the final solvent

concentration should be 0.1 %:

o Add 4 µl of solvent to wells containing 3.6 ml cell suspension.

o Add 396 µl semi-complete medium to the same wells and

carefully pipette up and down to mix.

GARDskin Page 25 of 41

- Unstimulated control: add 400 µl of semi-complete medium to the 3.6 ml cell

suspension, to achieve an in-well cell concentration and total volume equivalent

to test chemical treated samples.

- Incubate for 24 h±0.5 h at 37°C1°C and 5%0.5% CO

2

.

Figure 8. Schematic visualisation of test chemical addition to a GARDskin Main Stimulation.

Day 2

Cell harvest for RNA sample preparation and flow cytometry

From each cell culture well, prepare samples for RNA preparation and flow cytometry analysis

as described below.

Samples for RNA preparation:

- Resuspend the cells by carefully pipetting up and down, ~1 ml volume, swirl on

the bottom.

- Harvest 2 – 3 ≥1 ml samples from each cell culture well into separate RNase

free 1.5 - 2 ml tubes and keep the tubes at 2 – 8°C for now.

- Harvest all samples from all plates before continuing.

Samples for flow cytometry analysis:

- Harvest the remaining volume from each cell plate well and split into two flow

cytometry samples (~500 μl each).

- For the unstim ctrl four samples should be generated. Two for PI staining and

two for non-staining. If only one unstim ctrl well has been used, split this well

into four flow cytometry samples.

Note: Recommendation: clearly mark the two samples which should not be

stained.

- Store the flow cytometry samples at 2 – 8°C.

- Harvest all samples for flow cytometry from all plates before continuing.

Samples for RNA preparation:

- Centrifuge the samples for RNA preparation at 300-315×g for 5 min at 2-8°C.

- Remove supernatant carefully by aspiration. Optional: depending on format

aspirate only up to 12 tubes at a time, to avoid long-term contact with air and

degradation of the RNA.

GARDskin Page 26 of 41

- Quickly add 500 µl of TRIzol or equivalent reagent, as specified in the RNA

isolation kit protocol, to each cell pellet.

- Homogenize cells by vortexing the samples for 10-20 sec.

- Homogenized samples can be stored short-term in RT for maximum 1 hour,

long-term at -18°C or below (stable for one month), or

-80°C 10°C (stable for one year).

Note: Though several reagents can be used instead of TRIzol, for practical reasons, these

samples are called TRIzol samples throughout this protocol.

- Samples for flow cytometry analysis: Wash the flow cytometry samples by

adding 1 ml Wash buffer and centrifuge at 300-315xg, 5 min, 2-8°C.

- Remove the supernatant by aspiration and repeat the washing step.

- Prepare a staining solution (enough for 50 µl for each flow cytometry sample) of

50 µl Wash buffer and 1 µl Propidium Iodide (PI).

- Resuspend each sample in 50 µl of the staining solution.

Note: the two unstimulated cells which are unstained are resuspended in 50 µl

Wash buffer instead.

- Incubate in dark at 2-8°C for ~10 min.

- Wash the cells by adding approximately 1 ml Wash buffer and centrifuge at 300-

315xg, 5 min, 2-8°C.

- Remove the supernatant by aspiration and resuspend in appropriate volume

(FACSVerse: 200 µl) Wash buffer.

- Analyze the samples on a flow cytometer according to manufacturer’s

instructions (FACSVerse 60 – 120 µl/min). Record approximately and at least

10,000 events.

Analysis of Cell population

Analyze the flow cytometry results in the same way as for the cytotoxicity measurement and

calculate the mean Relative viability for each substance using Equation 3.

The purpose of the propidium iodide (PI) stained samples in the Main Stimulation is a Quality

Control of the Relative viability to ensure that the test chemical and controls passes the

relative viability acceptance criteria.

Relative viability acceptance criteria

- The unstimulated control should have an Absolute viability of ≥84.5%.

- The negative control should have a Relative viability of ≥95.5%.

- The positive control should have a Relative viability of ≥84.5%-95.4%.

- Test chemicals that are expected to induce cytotoxicity based on the cytotoxicity

assessment should have a Relative viability between 84.5%-95.4%.

- Test chemicals that are assayed at 500 µM, or at the highest soluble concentration,

should have a Relative viability of ≥84.5%.

If a test chemical or control does not pass the Relative viability acceptance criteria, either the

entire Main stimulation should be discarded or only the test substance replicate from a single

Main Stimulation should be discarded according to the decision tree below.

Procedures at failed Relative viability Quality Control

- If the Quality Control criteria is not reached for the unstimulated control

(Absolute viability ≥84.5%), the Main stimulation has failed and all samples are

discarded. A new Main Stimulation should be performed.

GARDskin Page 27 of 41

- If the Quality Control criteria is not reached for the positive control (Relative

viability 84.5% − 95.4%) the Main stimulation has failed and all samples are

discarded. A new Main Stimulation should be performed.

- If the Quality Control criteria is not reached for the negative control (Relative

viability ≥95.5%), the Main stimulation has failed and all samples are discarded.

A new Main Stimulationshould be performed.

- If the Quality Control criteria for the Relative viability is not reached for a test

chemical, discard its generated samples from this stimulation. The controls for

this Main stimulation may still be used for other test chemicals within the same

Main stimulation, but are not used for this test chemical. Include the test

chemical in a new Main Stimulation. If necessary, the Test chemical may be re-

analysed for cytotoxicity as described above in Cytotoxicity Assessment, before

performing a new Main Stimulation.

Part result:

For each test chemical and control, 3 replicate samples for RNA isolation with passed

Relative viability Quality Control are required. The replicates are generated in three

individual GARDskin Main Stimulations (i.e. all samples for RNA isolation generated from

test chemical stimulations and control stimlations have to pass the viability quality control

criteria within the same Main stimulation).

RNA isolation

The RNA isolation is recommended to be performed with maximum 24 samples at a time. One

vial of the replicate TRIzol samples generated from each Main Stimulation well is usually

sufficient to obtain enough RNA for the endpoint measurement. If, for any reason, the first

isolated sample does not meet the acceptance criteria, a second sample is generated, either

by isolating the final TRIzol sample, or, when 3 or more TRIzol samples were generated from

one well, by pooling two TRIzol samples onto the same spin column. For the second RNA

sample isolated, the sample ID is suffixed, distinguishing it from the first, failed, sample.

Total RNA is isolated from the TRIzol

samples using a commercially available kit and reagents.

Direct-zol RNA MiniPrep, Zymo Research, specified in Table 3, is used by the assay

developers and is therefore recommended. In general, the manufacturer’s instructions should

be followed.

Prepare the buffers and follow the protocol in the instruction manual included in the

recommended kit (Direct-zol RNA MiniPrep), but with the following adjustments:

- Thaw TRIzol samples on ice.

- DNase I treatment should not be performed.

- After the centrifugation with RNA Wash buffer, discard the flow-through of the RNA

Wash Buffer (re-use the collection tube) and perform an additional 1 min centrifugation

(10,000-16,000×g) to avoid RNA Wash Buffer residues in the eluate.

- Elute RNA by adding ≥25 µl DNase/RNase free water directly to the column matrix and

centrifuge at 10,000-16,000xg for 30 seconds (though not recommended in the

DirectZol protocol, the RNA can be eluted with as little as 20 µl of DNase/RNase free

water). If necessary to increase RNA yield, it is possible to perform a double elution by

loading the eluted RNA once again on the same column for a second centrifugation.

- The eluted RNA can be used immediately or stored at -70 – -90°C.

GARDskin Page 28 of 41

It is recommended that a small aliquot (2 µl) is stored separately or used immediately, for

quantification and quality control purposes.

RNA quantification and quality control

Analyze the RNA from each sample using an Agilent Bioanalyzer, or an equivalent instrument.

Follow protocols provided by the supplier. RNA concentration and quality should correspond to

NanoString recommendations. During test method development and validation, a sample with

an RNA Integrity Number (RIN) of 8.0 and above, as derived from the Agilent Bioanalyzer

2100, was considered a sample of high quality. Corresponding or otherwise equivalent RNA

quality metrics may be used to assure high quality RNA.

Part result:

For each test chemical and control, three RNA samples, each identified with a unique

Sample ID and passing the RNA Quality Control is generated.

GARDskin Page 29 of 41

GARDskin Endpoint measurement

The endpoint measurement of GARDskin is the mRNA quantification of the GARDskin

prediction signature (GPS) using the NanoString nCounter system. In the provided instructions

below the nCounter MAX system is used. If another equivalent nCounter platform is to be

used, refer to the manufacturer’s instructions for appropriate experimental procedure and

discuss with method developer.

The custom made CodeSet (i.e. a set of oligonucleotide probes representing the genes of the

prediction signature) has been developed by SenzaGen and NanoString. To place an order for

a batch of the CodeSet, please contact SenzaGen AB. It is not possible to use different

batches of CodeSets for analysis of the endpoint using the GDAA application. The nCounter

analysis is performed with maximum 12 RNA samples at a time (one cartridge and CodeSet).

Setting up a NanoString Hybridization assay

All hybridization reactions use a total RNA input of 100 ng. According to the protocol below,

the sample is added to the reaction in a volume of 5 µl. Thus, all samples are to be diluted to a

concentration of 20 ng/µl.

General Probe Handling warning: During setup of the assay, do not vortex or pipette

vigorously to mix as it may shear the Reporter CodeSet. Mixing should be done by flicking or

inverting the tubes. Do not spin any faster than 1000 x g for more than 30 seconds as this may

spin the CodeSet out of solution. Be aware that the maximum speed of a minicentrifuge is

usually >1000 × g and that the “pulse” option of a microcentrifuge quickly goes to >1000 × g.

- Heat a thermocycler to 65°C, with a lid temperature of 70°C. A time program can

be used. Note: Program the thermocycler using 15 µl volume, at temperatures

stated above.

- Thaw Reporter CodeSet and Capture ProbeSet at room temperature and store

on ice. Flick and spin down. Note: After thawing, inspect the tube of Reporter

CodeSet to make sure no colored precipitate is present. If you see a colored

precipitate, heat the entire tube to 75°C for ~10 min and cool at room

temperature before using.

- Thaw RNA samples on ice. Flick and spin down.

- Dilute all RNA samples to a concentration of 20 ng/µl using RNase-free water.

Label each tube with its Sample ID. Mix by flicking and inverting and spin down.

- Prepare a master mix by adding 70 µl of the hybridization buffer (provided in the

NanoString master kit) to the Reporter CodeSet. Carefully mix by flicking and

inverting and spin down.

- Cut a 12-strip of hybridization-tubes (provided in the NanoString master kit) in

half, if necessary to fit them into a centrifuge. Note that the hybridization-tube

strip has an orientation from 1-12, shown by the indent after the 1

st

and 8

th

position. Mark the tubes with Sample ID.

- Distribute 8 µl of the Reporter CodeSet master mix to each hybridization tube.

- Add 5 µl of diluted RNA sample to each hybridization tube. Carefully mix by

flicking and inverting and spin down.

- Add 2 µl of the Capture ProbeSet to each hybridization tube. Close the tubes

with plastic lids and carefully mix by flicking and inverting and spin down.

- Place the hybridization tubes in the preheated thermocycler and incubate for 24

±0.5 h.

Setting up a nCounter Prep Station Run

- Remove the cartridge from storage at -20 ±4°C and equilibrate to RT for ~30

minutes before the seal is broken.

GARDskin Page 30 of 41

- Remove 2 reagent plates from storage at 4°C and equilibrate to RT for ~30

minutes. Centrifuge the reagent plates 2000xg for 2 min, remove plastic lids

before installing in the Prep Station.

- Chose “Start processing” on the screen and select the high sensitivity mode.

- Install all components into the Prep Station according to instructions on-screen.

All required plastic material is provided in the NanoString master kit “prep pack”

(stored at RT).

- After 24h (±0.5 h) hybridization, remove the hybridization tubes from the

thermocycler and spin down. Lift the metal lid in the prepstation and place the

tubes without lids in the position highlighted on-screen. Orient the tubes so that

sample #1 is positioned to the left and position #12 is positioned to the right.

Close the metal lid.

- Initiate the run by following on-screen instructions. It is recommended to

supervise the prep station until it starts piercing the foil of the prep plates. If

reagents or plastics are not inserted correctly the Prep Station will have

detected it at this point and informed on the screen.

- Once the Prep Station protocol is finished, after approximately 3 h, carefully

remove the cartridge and place it on a lab-tissue and seal it with a provided

adhesive cover.

- Discard used material in the Prep Station.

- Proceed to Analysis with Digital Analyzer.

Analysis with Digital Analyzer

- Create a Cartridge Definition File (CDF) according to NanoString’s instructions,

using the highest field of view count, and upload it to the Digital Analyzer. The

file maps the reads from each lane in the cartridge to sample specific attributes.

Upload the created CDF-file to the Digital Analyzer prior to starting the analysis .

- Upload the RLF file to the Digital analyzer if it has not been added previously

prior to initiating the analysis.

- Place the cartridge in the Digital Analyzer chose “Add Cartridge” and follow

instructions on screen.

Note: If the Digital Analyzer is quantifying another cartridge, press pause and follow

the instructions to add the new cartridge.

- Follow the on-screen instructions to start the analysis, the analysis takes ~5

hours for a full chip and the instrument can run overnight.

- When the Digital Analyzer is finished, download your RCC files according to

internal documentation (FTP, email, and USB transfer of data is available). If

stored at 2-8°C, the cartridge can be rescanned at least once for at least two

weeks.

RCC file Quality Control

The output from each sample analyzed in the nCounter will automatically be quality controlled

with internal control probes included in the CodeSet.

For NanoString facilities not using the GARD Data Analysis Application (GDAA), each

acquired RCC-file should be quality controlled to assure that the nCounter analysis has been

successful. Samples that fail any of the below described critical quality criteria should not be

used for further analysis in the GARD™skin data analysis pipeline. The critical quality metrics

are imaging quality, linearity of the spike-in RNA control probes, limit of detection (LOD), and

binding density. The imaging quality is calculated as the ratio between the number Fields of

Views (FOV) (predefined in the CDF file as 555) and the number of successfully counted

FOVs. A ratio above 0.75 (>0.75) is required for a sample to pass the imaging quality control.

The linearity of the positive spike-in controls is calculated using the positive control probes

GARDskin Page 31 of 41

(POS_A-E) and their known RNA concentrations. The acquired counts for the positive control

probes and their respective concentrations should be logarithmized (log2) before calculating

the R

2

value of a linear fit to the data points. An R

2

value above 0.95 (R

2

>0.95) is required for a

sample to pass the linearity quality control. The LOD quality control uses all the negative

controls (NEG_A-H) and the positive control E (POS_E). The LOD is defined as the mean

counts of the negative control probes plus 2 standard deviations of the counts, see Equation 4.

(Equation 4)

Where μ and σ are the mean value and the standard deviation of the negative control probes’

counts respectively. For a sample to pass the LOD quality control, the positive control probe

POS_E must be above the estimated LOD (POS_E > LOD). The binding density is a measure

of the number of probes observed per cartridge surface area during the gene expression

acquisition in the Digital Analyzer. For a sample to pass the binding density quality control, the

binding density must be above 0.05 and below 2.25 (0.05< binding density <2.25). For a

summary of the critical quality control parameters, see Table 8.

Table 8. Summary of the critical RCC-file quality control parameters

Quality Metric

Critical parameter

Imaging Quality

>0.75

Linearity

>0.95

Limit of Detection

<POS_E

Binding Density

0.05 - 2.25

In addition to the above described critical quality control parameters, it is also recommended to

count the number of endogenous probes with 0 observed gene counts. If any samples contain

multiple endogenous genes with 0 observed counts, a plausible explanation could be that the

cartridge was analyzed with the wrong version of the RLF file. If this is the case, the affected

cartridge should be rescanned (within two weeks) with the correct version of the RLF file to